On September 8, 2021, the Hay Think team at the world’s leading provider of ultra-high printing accuracy (2μm) complex 3D micro/nano printing technology: CQMF Precision 3D Technology Corporation saw that CQMF is using 3D micro-nano printing technology to print ultra-high precision parts.

CQMF is the world's only 2μm precision 3D micro-nano printing technology solution provider. 3D micro-nano printing technology is a digital technology that is gradually being applied to the production of high-value products.

The research and development of ultra-high-precision technology plays a vital role in industrial development, but only a few companies in China can export technology. CQMF’s CTO Dr. ZOU said: “CQMF’s self-developed 3D micro-nano printing technology has made the company the world’s only 2μm precision 3D micro-nano printing technology solution provider. In March of this year, it won the 2021 Prism Award (Prism). Award)'Manufacturing category award. This award is the highest award in the field of optoelectronic technology in the world. This is the first time a Chinese company has won this award for its leadership in local original precision manufacturing technology."

CQMF's precision 3D printing technology has provided micro-nano 3D printing equipment, materials and printing services to nearly 700 companies and scientific research institutes in 25 countries around the world. At the same time, it also provides services to some well-known universities at home and abroad and some Fortune 500 companies. At present, CQMF technology supply is developing in the direction of globalization, and it is one of the rare domestic enterprises in China that provides technical support to the world's top 500. "

At present, high-precision manufacturing of complex small machinery has become a field where the global manufacturing industry is competing. This kind of high and new technology has a huge demand in the industrial field, but traditional manufacturing is difficult to get rid of technical disadvantages. Whether it is molds, CNC machining, or traditional 3D printing, there are pain points such as rough production and high cost.

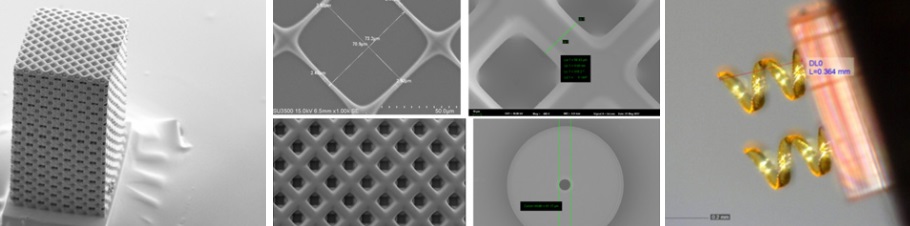

CQMF's ultra-high-precision 3D printing system can achieve the world's highest level of manufacturing accuracy of 2μm, and has the characteristics of high manufacturing accuracy, fast speed, low cost, and good stability. It can play an important role in industrial-grade ultra-high-precision manufacturing. "

CQMF is committed to the world's leading R&D and manufacturing of ultra-high printing accuracy (2μm/10μm/25μm) technology, with high-precision processing tolerance control capabilities (±10μm/ ±25μm/±50μm), equipped with tough resin, hard resin, and High-temperature resins, bio-resins and other printing materials enable the Nano 3D printing system to directly mold precision plastic structural parts and functional devices without the need for post-processing processes such as polishing, grinding, and spraying. The Nano 3D printing system can provide customers with mold-free ultra-high-precision fast proofing verification, and small-batch precision plastic parts processing.

Nano 3D printing equipment adopts PμSL: [PμSL: Projection Micro Stereolithography] technology, which is one of the few 3D printing systems in the industry that can achieve ultra-high printing accuracy and high tolerance processing capabilities. PμSL technology uses a high-precision ultraviolet lithography projection system to project the model to be printed onto the resin surface in layers for rapid micro-three-dimensional molding, and directly process three-dimensional complex industrial samples from the digital model. This technology has outstanding advantages such as high molding efficiency and low processing cost, and is considered to be one of the most promising micro-scale processing technologies. As a leader in the field of high-precision additive manufacturing, CQMF has established business cooperation with many world-renowned companies, including GE Healthcare, Johnson & Johnson, Denso, Amphenol, Tyco Electronics… Products are widely used in connectors, precision medical equipment, Consumer electronics, precision machining and other industries.

As the pioneer and leader of micro-nano 3D printing, CQMF's R&D team has more than 20 years of scientific research and engineering practical experience in the field of micromachining of three-dimensional complex structures. We will continue to provide simple and efficient technical support solutions for the process and material problems that customers may encounter in the development of new products. The 3D printing system developed by the company has also been used by many top universities and scientific research institutions in the world, such as Tsinghua University, Peking University, Zhejiang University, Beihang University, PetroChina, Chinese Academy of Sciences, Nottingham, UK, Dresden Institute of Technology in Germany, Nanyang Technological University in Singapore.