The proton exchange membrane/Perfluorosulfonic Acid Ion-Exchange PFSA Membrane for Fuel Cell is a solid polymer electrolyte with excellent heat resistance, mechanical properties, electrochemical properties and chemical stability. It can be used under harsh conditions such as strong acids, strong bases, and strong oxidants. Fuel cells prepared by proton membranes can be widely used in passenger cars, commercial vehicles, forklifts, unmanned aerial vehicles, backup power sources, portable generators, cogeneration systems for homes and commercial buildings, etc.

Proton exchange membrane/Perfluorosulfonic Acid Ion-Exchange PFSA Membrane is also called "hydrogen fuel cell chip".

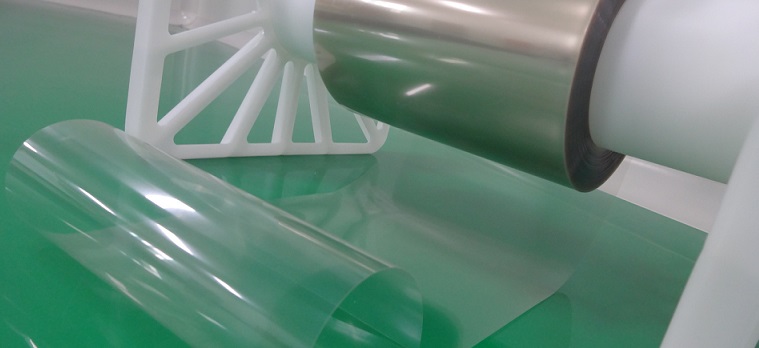

Different from the traditional automobile engine structure, the core of the hydrogen fuel cell automobile engine is a stack, and the key of the stack is the membrane electrode. The membrane electrode is mainly composed of a proton membrane, a catalytic layer, a diffusion layer, etc. The most important thing is this thin as a cicada. Wings, a proton exchange membrane with a thickness of only ten micrometers-after hydrogen is injected into the battery anode, under the action of a catalyst, the hydrogen’s electrons and protons are separated. The proton exchange membrane selectively allows only protons to pass through to the cathode, and electrons from the external circuit When it reaches the cathode, electricity is directly generated instead of hydrogen combustion to generate electricity.

At present, there are only two companies in the world that can meet the commercial technical requirements of hydrogen fuel cells for vehicles and realize commercial production, and SDDY is one of them and another one is Gore.

SDDY Hydrogen Material Technology Corporation has mastered the key core technology of hydrogen fuel cell vehicles-Proton exchange membrane.

SDDY was previously committed to the R&D and manufacturing of chlor-alkali ion membrane products. The chlor-alkali ion membrane and fuel cell proton membrane belong to two major industries, but both belong to the fluorination industry and share the same raw material-perfluorosulfonic acid resin. In the process of developing ionic membrane, SDDY already has the upstream industrial chain from fluorite to tetrafluoroethylene, and then to perfluorosulfonic acid resin, and the downstream research and development is more effective;

SDDY perceives that hydrogen fuel cells will be a major development trend for new energy vehicles, so Y invested 1 billion yuan to build a world-class proton exchange membrane research institute. The company has successively introduced more than 260 PhDs and experts from internationally, Peking University, Tsinghua University, Chinese Academy of Sciences, etc., and established 6 R&D centers in Shanghai, Beijing, Shenzhen, Japan, Canada, and Germany… The largest one-year R&D project investment is as high as 500 million yuan..

At that time, the AFCC company (Mercedes-Ford Joint Venture Fuel Cell Company) based in Vancouver provided technical guidance, test evaluation and improvement suggestions for SDDY based on the actual market application of hydrogen fuel cells.

With the advent of the global carbon neutral era, the prospects for the hydrogen car market have gradually become clear. In 2012, AFCC launched a global supplier screening, including China SDDY, American Gore, DuPont, Japan's Asahi Glass, Germany's BASF, and more than a dozen companies sent samples to participate in the evaluation. In the end, SDDY was successfully selected, and the two parties began to sign a cooperation agreement to tackle key issues such as mass production stability, adaptability and economic efficiency.

On November 27, 2016, AFCC fuel cell CEO Andrews came to SDDY and personally handed over the fuel cell proton exchange membrane’s certificate of successful 6,000-hour life acceleration test to SDDY. At the same time, the two parties also signed the "Joint Development Agreement", which is a comprehensive Deepen strategic cooperation.

Obtaining this test certificate means that SDDY's fuel cell proton exchange membrane has reached the world's first-line level and can be used in the mass-produced hydrogen fuel cell vehicles of Mercedes-Benz and Ford. It also means that it has obtained a "pass" to enter the global hydrogen fuel cell vehicle market. .

At present, only two companies have passed the test in the world. In addition to SDDY, the other is Gore.