The annual event of the coal industry-the 6th Clean Coal Efficient Utilization Exhibition came to an end at the Taiyuan Coal Trade and Exhibition Center. The 2020 China Coal Clean and Efficient Utilization Conference and a series of forum activities will also be held concurrently. The three-day exhibition attracted 396 exhibitors, with a total exhibition area of 36,000 square meters, and nearly 29,166 professional visitors visited the site.

JSJX Intelligent Industrial Technology Group launched a customized belt conveyor system solution for intelligent logistics and intelligent transportation at this exhibition; the new world's first 630kW permanent magnet direct-drive electric roller, a permanent magnet tailored for personalized transportation Roller and high-efficiency energy-saving frequency conversion control products, unique correction series.

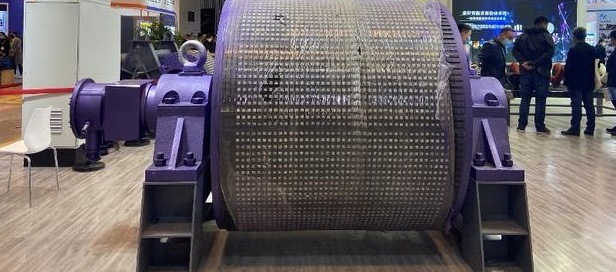

630KW permanent magnet direct drive electric drum

The 630KW series permanent magnet direct drive electric drum developed by JSJX adopts permanent magnet motor technology, direct drive transmission technology, outer rotor motor technology, and a new type of drive equipment that combines the innovative design of the drive drum. It is suitable for driving various types of belt conveyors. Through the innovative design of the stator teeth and yoke separation structure, the torque density of the permanent magnet outer rotor motor is improved, and the problem of low torque density is solved. It has a high-efficiency cooling system with a low-speed and high-torque external rotor permanent magnet direct drive drum. Effectively avoid excessive local temperature rise; the heat dissipation calculation model of the stator punched silicon steel is proposed, and the original punched fin is used as the heat dissipation channel carrier, which effectively saves space and improves the cooling capacity of the low-speed and high-torque outer rotor permanent magnet direct drive drum And torque density, the total transmission efficiency can reach 94.9%, has excellent starting, speed regulation characteristics and energy-saving effects, and has broad application prospects and economic and social benefits.

Honor and technical strength

.China industry standard setter for permanent magnet direct drive drum motor

.The world's first 315KW explosion-proof certification winner

.Obtained 106 national safety standards certification

.The only winner of air cooling technology certification

.The exclusive owner of the most authoritative testing equipment

.Permanent magnet direct drive electric drum industry leading brand

.The pioneer of permanent magnet direct drive electric drum technology

.Listed in China National Energy Conservation Catalog

.Stand-alone safe operation for more than 15,000 hours

.Nearly one hundred 315KW permanent magnet drums used in underground