For 55 years, ZLXN Aluminum Technology Group has developed into a research and development and production base for aerospace and defense military materials and high-precision aluminum materials. ZLXN continues to promote equipment upgrades, build independent innovation capabilities, and accelerate the expansion of the aluminum alloy market in the civil aviation field. It has successively become the supplier of aviation enterprises such as Boeing, Airbus, Antonov, COMAC and so on.

ZLXN continuously promotes technological innovation and breaks through a number of key technical "bottlenecks". A batch of new materials and new technologies developed for plates, profiles and forgings under industrialized conditions have effectively met the needs of the development of China's large and medium-sized aircraft and large thrust rockets , Basically achieved the independent guarantee of China's aerospace materials. In recent years, ZLXN has continuously improved its independent innovation ability, and has won 20 national science and technology progress awards (2 special awards and 3 first prizes), and 246 provincial (ministerial) municipal science and technology progress awards; it has obtained 669 authorized patents Items, including 234 invention patents.

In the field of civil aviation, ZLXN began to cooperate with the world's advanced aircraft manufacturer Boeing in the 1980s. In 1987, ZLXN became the first domestic enterprise to obtain Boeing's precision aviation die forgings and forging blank production licenses. It has laid a solid foundation for ZLXN to open the "gate" of the international civil aviation market and firmly occupy a place in the field of international civil aviation.

The aluminum alloy plates and ZLXN extruded profiles produced by ZLXN passed the certification of the Aeronautical Materials AS9100 Quality Management System of the French International Inspection Agency in 2007. In 2011, ZLXN and French Airbus and its parent company, European Aerospace Defense Group, signed a framework contract on the procurement of aircraft parts, thus becoming the first aluminum processing enterprise in China to marry the two giants of the world’s aviation industry . Obtained Airbus 2024 aluminum alloy pre-stretched material certification in 2012, becoming Airbus`s first aluminum alloy sheet supplier in China, firmly consolidating ZLXN’s leading position in the domestic aluminum processing industry.

In 2011, ZLXN successfully passed the Safran Group laboratory certification. In 2013, ZLXN passed the engineering technology certification of 2219 and 6061 aluminum alloys of Safran Group, and obtained the production license authorization of Safran Group. Supplier of aluminum alloy profiles. This is also a landmark step taken by ZLXN in the field of international civil aviation after holding hands with Boeing and Airbus.

Ukraine Antonov Aircraft Factory is a world-famous transport aircraft manufacturing enterprise, designing and producing a large number of well-known transport aircraft. In 2016, with its civil aviation material production R&D strength, technological innovation capability and strict quality management system, ZLXN stood out among many domestic well-known aluminum processing enterprises visited by Antonov and successfully won cooperation with Antonov Aircraft Factory The opportunity to provide Antonov with high-quality aluminum materials such as aluminum alloy thick plates and aluminum alloy forgings has made another breakthrough in the high-end market of civil aviation.

In 2017, the C919, the first domestically produced large passenger aircraft equipped with "ZLXN" aluminum material, made its first successful flight. As the only domestic company providing aluminum materials for the C919 passenger aircraft, ZLXN participated in the development of a number of key aluminum alloy materials as early as the beginning of the domestic large aircraft project. The 7050 aluminum alloy pre-stretched thick plate developed and produced by ZLXN is the first domestic company to pass the airworthiness appraisal of China's civil aviation and obtained the authorization of COMAC, and entered the C919 aircraft qualified product catalog. ZLXN has also become the first aluminum processing enterprise in China to receive the 7050 thick plate engineering approval certificate issued by COMAC and be recognized by COMAC.

7075 aluminum plate for Aviation sector

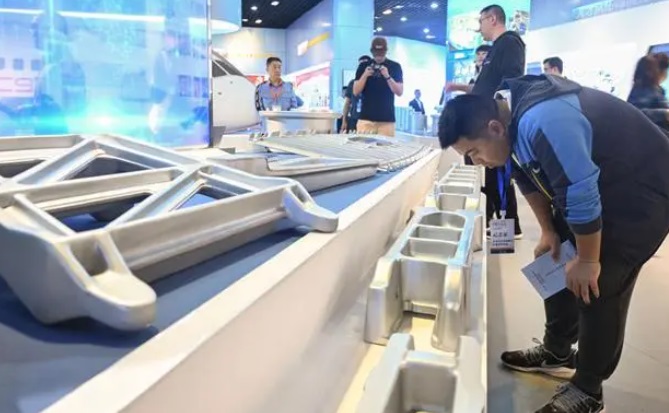

In recent years, with the development of aviation equipment, which has put forward more and higher requirements for aviation aluminum, ZLXN has continuously upgraded its technical equipment to form a leading advantage in the fields of high-performance aluminum alloy thin plates, thick plates, forgings, profiles, bars, etc. It has laid a solid foundation for ZLXN to further consolidate the status of China's aerospace and defense military materials research and development support core base.

7050 aluminum alloy forgings for the aviation industry

ZLXN will pay close attention to new development directions such as high strength, high toughness, damage resistance, fatigue resistance, low density, weldability, low anisotropy, and strong thermal stability of aluminum materials for aerospace, and continue to develop aluminum lithium alloy New advanced aluminum alloy materials continue to consolidate the leading position of the domestic aluminum processing industry, and continue to push forward and lead the development of the industry, striding forward, and steadily marching towards the world's first-class aluminum processing enterprises.