The photolithography machine is the core equipment for chip production. The optical quartz glass and components used in the photolithography machine are known as the "lung of photolithography" and are essential components in the photolithography machine.

SHJZ Ultra Precision Technology Corporation, through continuous independent research and development, innovation and development, continuous comparison and adjustment, repeated iteration, and finally established a stress processing model and process database with full independent intellectual property rights, and used unique low-temperature hydrogen doping technology and multi-mode combined processing technology based on ring polishing, ion beam, etc. to achieve ultra precision and ultra smooth processing of photolithographic quartz glass components, This further narrowed the technical gap between China and international giants, and broke the status quo that the optical quartz glass ultra precision components for semiconductor lithography mainly rely on imports.

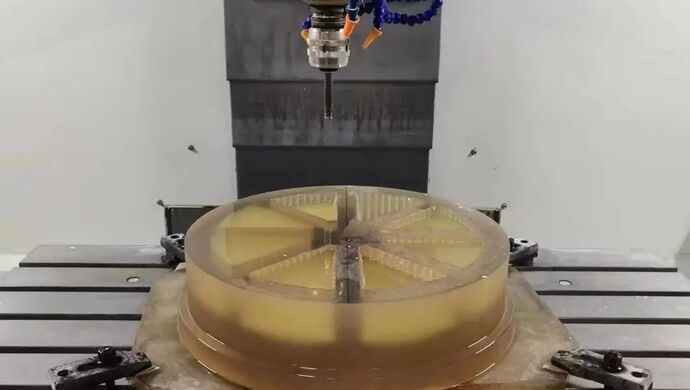

Recently, in the production workshop of SHJZ, several ultra-high precision CNC machining centers and CNC polishing equipment are operating at full capacity, and the operators stand aside to closely monitor the operation of the equipment.

At the production site, Hay Think team saw that what the ultra precision processing equipment is processing is the ultra precision lithography sucker used for the lithography machine, which is also the highest precision level that the company's products can achieve at present.

It is reported that the R&D personnel have optimized the combination of classical polishing, high-speed polishing and ion beam polishing. The roughness of these ultra precision optical components produced is less than 0.25nm, which can greatly improve the quality of photolithographic imaging.

"The lithography machine has very high requirements for the accuracy of the exposure stage, which needs to be accurate to the nanometer level. Once the accuracy of the displacement stage is in question, the chip produced cannot be used. The CTO Dr. Qin said while taking out a finished ultra precision lithography sucker with a diameter of about 30 cm and a thickness of about 4 cm, which is lined with hundreds of small round holes and several thick and thin grooves of toothpicks. This seems to be a simple structure, in which many years of technical precipitation has been condensed And continuous technological innovation.

With the continuous improvement of the R&D capability and processing technology of the enterprise on the highly homogeneous quartz materials for photolithography, SHJZ provides the downstream photolithography enterprises with "customized services" for high-precision components.

"It took SHJZ nearly two years to finally achieve the surface roughness of optical elements being less than 0.25 nm. This latest ultra precision lithography chuck is a big step from experimental data to mass production. "Don't underestimate this sucker. The hole on the sucker is big and leaks, but the suction is not enough. The final product should not only ensure that it can hold the silicon chip, but also not produce any wear. Six batches of products were tested before and after, so that the stress treatment model, process data and actual production can be perfectly combined, and the probability of problems can be minimized.

In addition to the continuous improvement of processing accuracy, enterprises also have "unique secrets" on how to reduce the risk of cracking in the process of material processing and use.

Hay Think team saw on site that each raw material will be soaked in a special buffer solution after the first process – cutting, and then sent to the finishing workbench after repeated treatment.

Dr. Qin said: "Optical glass is a brittle material. After rough processing, invisible cracks will appear on the edge. If left unchecked, it will increase the risk of cracking during fine processing." To solve this problem, the research and development team independently developed a nano binder. This binder should not only penetrate into the cracks well, but also have a strong pull force, which is strong enough to firmly "pull" the cracks and prevent the glass cracks from continuing to grow, Ensure that the glass is stable and not broken during finishing. "At present, SHJZ is the only one in China that can achieve this level.

It is reported that SHJZ is able to realize the stress relief treatment of high-precision quartz materials, with the stress birefringence less than 2 nm/cm. The products have gradually achieved mass production and are favored by many scientific research institutions.

Customer Reference

China Aerospace Science and Technology Group, China Electronics Technology Group…

At the same time, it provides teaching and research services to major research institutes of the Chinese Academy of Sciences to research new science and technology applications in the aviation and space fields, as well as to Tsinghua University, University of Defense Technology, Peking University, Shanghai Jiao Tong University, Fudan University, University of Science and Technology of China and other national key universities.