On the evening of October 14, China's precision aluminum alloy die-casting and forging parts manufacturer NBXS Light Alloy Technology Company announced that the company plans to raise 1.2 billion yuan to invest in new energy automotive precision casting and forging parts project (Phase II) and lightweight automotive zero Parts manufacturing projects.

Xu Dong, chairman of NBXS, revealed that in order to complete the sales of this expanded product, the company has actively carried out preliminary communication and technical development with customers. Or its first-tier suppliers have carried out intentional cooperation and negotiation, and some customers plan to send samples and carry out comprehensive cooperation in the second half of this year. At the same time, the company has reached a cooperation with Tesla China, which further guarantees the capacity digestion of this expansion.

Customers Reference

NBXS has become a strategic partner to many world-renowned OEMs:

Tesla,BMW, Mercedes-Benz, Audi, Ford, Porsche, Chrysler and other OEMs

and Tier 1 suppliers such as ZF, CATL, Polaris, NextEv and Magna. Owing to its great capabilities in new project development and quality control, The company was awarded the top 10 Excellent suppliers from Tesla and acknowledged by many other customers.

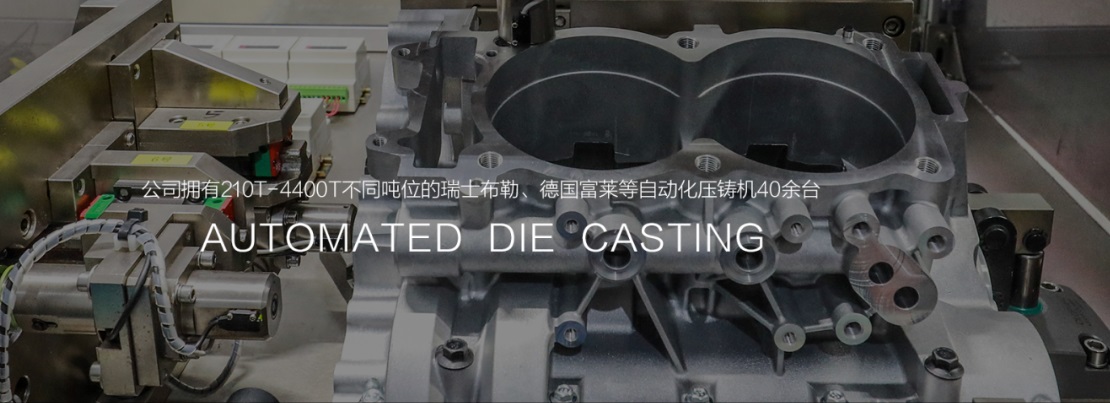

NBXS Dong Mi Zhou Xiaofen introduced: "This expansion of the company will establish an advanced production line integrating raw material production, automated manufacturing and quality inspection. The high-end castings and forgings produced are mainly used for automotive suspension and steering systems."

The products produced by the company's new energy vehicle precision casting and forging project (total of Phase I and Phase II) can be matched to meet the needs of 700,000 to 900,000 vehicles. She said, "With the rapid development of automotive lightweighting, the future penetration of aluminum alloy forgings will further increase, and the market prospect of aluminum alloy forgings for automotive chassis suspension systems is huge."

It is reported that the company's new project "new energy automotive precision casting and forging products" and "automotive lightweight parts products" will increase production capacity by 6.85 million and 7.2 million respectively.