2020 is the fastest iterative year for photovoltaic cell module technology development. In order to solve the contradiction between solar cell conversion efficiency and cost considerations, the industry is trying to promote and use graphite carrier technology solutions. Because the graphite carrier plate that meets the requirements of this scheme needs to be imported, and the price is relatively high.

The continuous development of the photovoltaic industry has also allowed researchers to focus on the application of composite materials. JSBS Carbon Fiber Technology Co., Ltd. has been committed to the development and promotion of carbon fiber composite materials. It has produced a high-temperature resistant carbon fiber carrier board. After experimental tests, it is found that this type of PERC (passivated emitter back contact battery) coating and back The carbon fiber carrier board of the solar cell coating process such as passivation can not only maintain the stability of the material at high temperature, but also show obvious advantages in reducing the edge effect during the coating process and increasing the productivity.

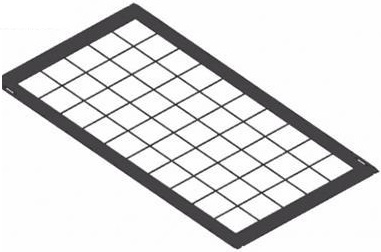

The carbon fiber solar cell silicon wafer carrier is composed of a carrier main body, a carrier guide bar and a carrier reinforcement rib. The carrier board reinforcement ribs are perpendicular to the carrier board guide bar; the carrier board body uses high-temperature, corrosion-resistant and high-strength carbon fiber materials; the carrier board body has an array of rectangular holes, and the rectangular holes have two steps on the circumference, the first of which The step and the side wall form a first groove, the side of the first step and the second step and the side wall form a second groove, and the peripheral side of the silicon wafer contacts the second step surface to be supported by the second step. The carbon fiber photovoltaic carrier board uses carbon fiber composite materials, which is convenient for later cleaning. The structure of the carrier board strengthens the anti-deformation ability of the carrier board; the first step and the second step are arranged to make the hollow area under the silicon wafer larger and reduce silicon The contact area between the chip and the carrier makes the heating efficiency of the silicon chip higher.

The carbon fiber carrier board can be combined with the solar cell sheet and the transparent plastic packaging material layer to form a carbon fiber solar panel. First, the carbon fiber cloth is prepared into a horizontal carbon fiber board by hot pressing, and the solar cell sheet and the transparent plastic packaging material layer are stacked on another horizontal carbon fiber carrier in order of the transparent plastic packaging material layer and the transparent plastic packaging material layer of the solar cell sheet. The horizontal pre-compressed solar module is made; on another horizontal carrier, the horizontal carbon fiber board plastic encapsulation material layer is horizontally pre-compressed, and the transparent plastic encapsulation material of the solar module is stacked neatly and then pressed to form a horizontal carbon fiber solar panel. Then, the horizontal carbon fiber board and the solar module are pressed into a whole through a laminator, which solves the technical problems of carbon fiber cloth wrinkles, bubbles, delamination and displacement during the preparation process of the carbon fiber board.

With the vigorous advancement of the construction of wind power and photovoltaic power generation by the China Energy Administration, the application of carbon fiber composite materials on the carrier board is also of great significance to the improvement of its industrial production value.