New technology for steel bridge deck paving: UHPC ultra-high performance concrete successfully developed and applied

The paving technical problems caused by the large deformation and large shear stress of the orthotropic steel deck of the super large river-crossing bridge have always been a worldwide problem. The Jiangyin Bridge, Runyang Bridge, Sutong Bridge, Taizhou Bridge, Chong Most of the steel decks of large river-crossing bridges such as Qi Bridge adopt epoxy pavement structure.

JSZK Pavement Material Technology Group has developed UHPC cement-based paving materials for steel bridge decks, breaking the monopoly of traditional epoxy paving layers and marking a solid step for modern roads and bridges in the new development of steel deck construction technology!

Ultra-High Performance Concrete: UHPC is characterized by ultra-high strength, toughness and durability, and overcomes the shortcomings of insufficient toughness of traditional cement-based materials. It can be used as a permanent paving structural material for steel bridge decks to achieve orthotropic steel bridge decks. The rigidity is reinforced to achieve the purpose of delaying the fatigue damage of the orthotropic plate and the pavement. The material has the characteristics of no-steam curing, low shrinkage, and high elastic modulus. Under normal curing conditions, the compressive strength can reach 120MPa, the drying shrinkage deformation is ≤500με, and the elastic modulus is about 30~35GPa.

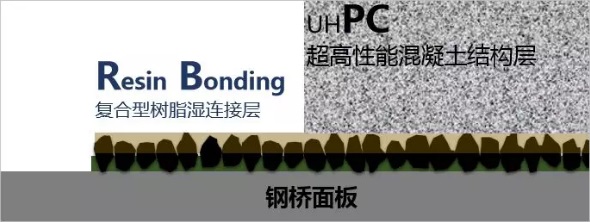

The UHPC pavement structure adopts a rivet-free resin connection method to avoid stress damage to the steel bridge deck caused by the conventional welding stud connection method. Compared with the epoxy pavement structure under the same conditions, UHPC pavement greatly reduces the stress on the steel plate and improves the structural rigidity of the steel bridge deck.

In 2019, JSZL conducted a UHPC pavement test section study at the most unfavorable position of the 1/4 span of the South Branch Suspension Bridge (Yang-Zhen direction) of Runyang Bridge. The test section is 140m in length, 15m in width, and about 2100m2 in area. This test section is constructed It is the first trial of ultra-high performance asphalt concrete UHPC pavement structure on a domestic operating bridge in China. After follow-up observation and performance analysis, compared with epoxy paving structure under the same conditions, the stress of steel plate under UHPC pavement is reduced by about 40%, and the rigidity of steel bridge deck structure is increased by more than 50%. At present, the test section is in good condition and has no disease damage.

In 2020, JSZL's UHPC products will implement the full bridge half (Yang-Zhen direction) UHPC steel deck pavement replacement project on the north branch cable-stayed bridge of Runyang Bridge. Including emergency lanes), with a total pavement area of 11370 square meters, UHPC steel bridge deck paving technology is expected to be further promoted and applied, and greater benefits will be achieved.