As a leading intelligent logistics system integrator and logistics equipment manufacturer in China, in recent years, HFJS Intelligent Technology Group has continued to invest in core equipment such as AGV based on its rich integration experience, and is committed to providing industry customers with basic equipment to One-stop service for upper-level logistics system design.

Developed the China first climbing AGV robot

HFJS Sales Director Han Jie mentioned in an interview with reporters: "One of the advantages of HFJS in logistics integration is that all AGV products, algorithms and scheduling systems in the project are developed and produced by us, which can guarantee the products to the greatest extent. Quality, give customers the best experience."

In recent years, Jing Song will have brand new AGV products available every year, and this year is no exception.

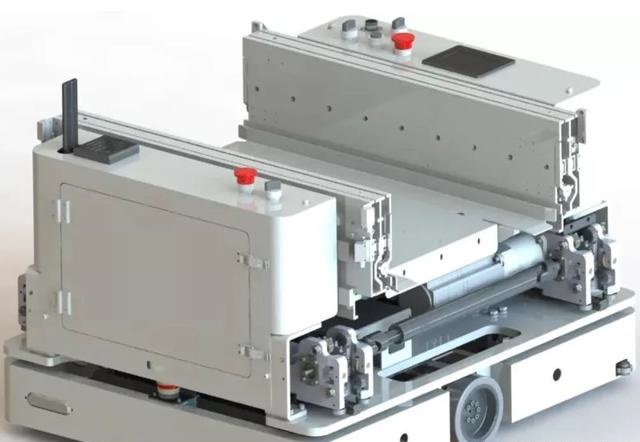

At this year's CIIF, China's first "climbing AGV robot" developed by HFJS was officially unveiled. This product realized the perfect integration of the AGV horizontal handling function and the three-dimensional shelf lifting storage. According to Han Jie, "This product is developed on the basis of stacker, multi-layer shuttle, AGV design, manufacturing, and application requirements, and is compatible with multiple functions such as AGV three-dimensional storage and picking."

In the navigation mode, the "climbing AGV robot" adopts two-dimensional code, visual navigation and positioning, and 360-degree rotation; in terms of mechanical design, it is equipped with customized telescopic forks, sprocket-type climbing tracks and shelves up to 10 meters in height; software system design Equipped with a brand-new picking method and location strategy, a brand-new software scheduling management system; and it supports the storage and picking of cartons/bins under 50KG, the running speed can reach 1.5m/s, and the lifting speed can reach 0.3m/ s. The application of "climbing AGV robot" can realize the direct handling of cargo storage positions and cargo handling stations, as well as multi-vehicle collaborative access, handling, and picking operations, which improves storage flexibility and efficiency, and realizes three-dimensional application technology innovation. It breaks the restriction that the AGV robot can only move and carry goods on the ground.

In addition to the climbing AGV, HFJS's other main product-the high-position forward stacking forklift AGV is also full of highlights. According to Han Jie, “This product is tailor-made to solve the uneconomical transformation of the old factory building's three-dimensional warehouse. The maximum load capacity can reach 1.5 tons, and the fork can reach 8 meters. The mast drives the fork to move forward during operation. Extend out of the front wheel to pick up or put down the goods. When walking, the fork takes the goods back, so that the center of gravity of the goods is within the supporting surface; below 8 meters, it completely replaces the stacker and realizes high-bay storage logistics automation with a higher cost performance This product is mainly used for the distribution of raw materials on the production line, the transportation of semi-finished and finished products, and the high-level palletizing of factory warehouses."

The navigation method has always been the core of AGV development. In this regard, Han Jie said: “Considering the coordination of environmental adaptation, at present, the navigation methods of HFJS AGV products are mainly based on laser slam, QR code navigation and visual texture. Lord, we have different adaptation schemes for different scenarios."

HFJS`s AGV annual sales growth rate has exceeded 30%, and based on project integration capabilities and high-quality core equipment, HFJS smart logistics solutions have been widely implemented in food, chemical, textile, automobile manufacturing and other industries.

Customer Reference

China State Grid, China Tobacco, People's Bank of China, GM,Total Hutchinson, Geely Automobile, Guoxuan Hi-Tech [Volkswagen Holding Company], Qingdao Metro…