ZJSY Electrode Material Technology Inc) is a specialized manufacturer of high quality electrode material for metallurgical industry.

ZJSY specializes in Permanent Stainless Steel Cathode Plate and Bipolar 4 Contacts Capping Board,With independent intellectual property rights,ZJSY currently has 42 product patents, including 16 invention patents and 2 software copyrights. The company's products are sold to domestic large and medium-sized enterprises such as North International, Daye Nonferrous, Guangxi Jinchuan, Jiangxi Copper, Tongling Nonferrous, Xiangguang Copper, Yuguang Gold and Lead, Zijin Mining, China Gold Group, China National Nonferrous Metals International, China Railway Group, etc. The products are exported to overseas markets such as Congo (Kinshasa), Congo (Brazzaville), Zambia, Myanmar, Kazakhstan, etc., and have won praises from customers.

Products

Permanent Stainless Steel Cathode Plate

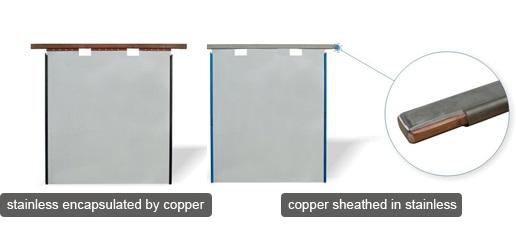

ZJSM with the maximum capacity of 160,000 sets of new cathode plates per year and 50,000 sets of refurbished cathodes per year. 2 types of permanent cathode plate could be manufactured and supplied according to detail application demands: “stainless encapsulated by copper/Copper Clad Stainless Steel Cathode Plate” has better conductivity, while “copper sheathed in stainless” provides higher corrosion resistance.

Bipolar 4 Contacts Capping Board

The Bipolar 4 Contacts Capping Board was invented in 2001 with the registered patent, which has advantages as below:

1. Evening current distribution in tank cells, reducing short circuit or broken circuit problems;

2. Evening thickness of cathode copper, and improving quality of copper product;

3. Increasing current efficiency;