On November 6th, recently, Chinese leading light alloy technology company, HJYJ Light Alloy Material Technology Group, took the lead and jointly developed China`s first "3.35m diameter aluminum-lithium alloy circular spinning part" in conjunction with the China Launch Vehicle Design Department. . It marks a major breakthrough in China's launch vehicle fuel tank manufacturing technology!

On China`s active rockets, each rocket`s fuel tank has two bottoms. The bottom of each box looks like half a watermelon. The traditional craft is "tailor-welded" made of 8 melon petals, 1 top cover and 1 transition ring. Counting down, there are a total of 10 main welds on the bottom of each box.

According to Wen Tao, deputy chief engineer of the spinning project, a rocket usually has 26 bottoms, about 260 welds, and a total length of nearly one kilometer.

The weld is the weakest link on the bottom of the box because it destroys the continuity of the material. Defects such as pores, deformation and cracks are prone to occur during welding, which affect the reliability and qualification rate of the bottom of the box. Once the weld is cracked, it will even cause fuel leakage, affecting the success or failure of the rocket launch. Therefore, each box bottom must undergo strict quality inspection before delivery.

"Furthermore, the weld is thicker, which will increase the weight of the rocket. After the weld is eliminated, the rocket can lose 60 kilograms." Wen Tao said.

Change "Tailor Welding" to "Integral Forming"

The reason for the occurrence of welds is due to the "tailor welding" production process. Before welding, each melon petal and top cover must go through more than ten processes such as blanking, quenching, deep drawing and trimming. Therefore, the bottom of the rocket case has always been the product with the most complex structure, the most difficult manufacturing, and the longest production cycle among the components of the rocket tank.

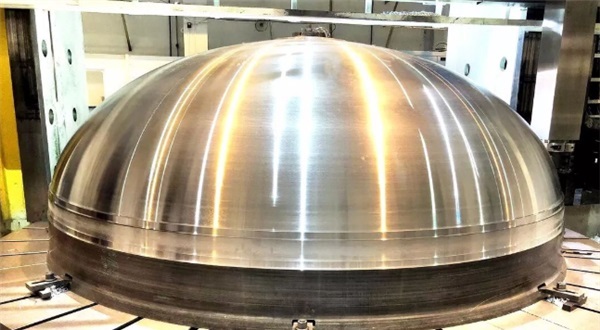

Aluminum-lithium alloy box bottom formed by one-step spinning

Wen Tao introduced that the "3.35m diameter aluminum-lithium alloy box bottom" adopts the integral spinning forming process, that is, a piece of plate is formed in a single step through a mold through a numerical control program, and is formed in one step.

Integral spinning forming, less manufacturing process, short cycle, and high reliability, there is no weld on the whole bottom of the box. It turned out that the production cycle of a box bottom took two to three months, and now it can be completed in 15 to 20 days.

Provide important support for the development of heavy rockets and new generation manned rockets

Internationally, the bottom of the aluminum-lithium alloy box represents the development direction of the carrier rocket fuel tank. The overall spinning process is the general trend, but its overall formation is very difficult. At present, only the United States, Japan, and Europe have mastered this technology.

For a long time, the first to third generation conventional aluminum alloy materials have been used in China's launch vehicle tanks, and the fourth generation aluminum-lithium alloy materials have not been successfully applied.

Wen Tao introduced that aluminum-lithium alloy is an advanced lightweight structural material. Its biggest advantage is its low density and high strength. The use of this material can reduce the weight of the arrow body structure by more than 15% and increase the carrying efficiency by 20%, which is of great significance for the improvement of large-scale launch vehicles with higher carrying capacity.

Compared with conventional aluminum alloys, aluminum-lithium alloys are not easy to form, and overall forming is even more difficult. HJYJ has overcome the four major technical difficulties of box bottom deformation resistance, forming temperature zone, forming path, deformation amount and pass distribution through hundreds of tests and a large number of accurate calculations. The first trial-produced aluminum-lithium alloy box bottom was successful.

3.35m aluminum-lithium alloy box bottom spinning parts

The successful mastery of the process of "aluminum-lithium alloy box bottom integral spinning forming" will provide important technical support for the development of China's heavy-duty launch vehicle and a new generation of manned rockets.

Wen Tao introduced that it is only the first step to overcome the forming process of "3.35m diameter aluminum-lithium alloy box bottom". In the follow-up, they will continue to trial-produce the "5m aluminum-lithium alloy box bottom" and realize the leap from forming the bottom of the rocket box from having mold to without mold.