Microspheres refer to spherical particles with very small sizes. "It looks like a microsphere is a simple sphere, but like a chip, the smaller the size, the more difficult it is to manufacture accurately. Once the size drops to the nanometer and micrometer level, the technical difficulty required is also huge." SZNW Technology Group Chairman Jiang Biwang recently told the Hay Think team that the microspheres used in the fields of biopharmaceuticals, liquid crystal displays, and IVD were basically dependent on imports, and were highly monopolized by very few foreign companies in almost every segment.

"Without microspheres, China's biomedical industry cannot produce a single drug, even the display screens of mobile phones and computers. In addition, the microspheres needed in the fields of nucleic acid testing, in vitro diagnostics, and water treatment in nuclear power plants are also not available. Relying on imports, once the supply of import channels is cut off, these industries will face a huge impact, and the risk factor is very high." Jiang Biwang said.

It is precisely the importance of nano-microsphere materials as basic materials in modern industry, and its preparation and application are listed as one of the 35 "bottleneck" technologies that restrict China's industrial development.

Precision manufacturing of microspheres

At present, almost all high-performance, high-value-added nano-microsphere materials are monopolized by foreign countries. For example, spacer silicon balls for liquid crystal displays are only produced by Ubo Nitto in the world; while plastic spacer microspheres are monopolized by Japan's Sekisui and Hayakawa; The separation and purification medium microspheres used in biopharmaceuticals and the silica gel packing microspheres used for analysis and detection are monopolized by Europe and the United States. However, the preparation and application of microspheres have a high technical threshold, involving cross-technology in many fields such as chemistry, biology, materials, and chemical engineering. Therefore, to develop microsphere products for different applications, close cooperation in different high-precision fields is required.

According to Jiang Biwang, the current microspheres produced by the international giant`s microsphere manufacturing process have a wide particle size distribution. In contrast, SZNW’s precision manufacturing technology can produce precise particle size and highly uniform microspheres according to actual needs. Therefore, the performance of microspheres can be improved to meet the needs of high-end products.

SZNW's microsphere products have precise particle size and high particle size uniformity, and the coefficient of variation of particle size distribution can be less than 3%, while the current traditional products on the market generally exceed 10%.

"In the field of drug separation, the smaller the size of nano-microspheres, the more uniform the particle size, and the higher the separation efficiency. After the microspheres manufactured by traditional methods, further screening is required to select microspheres of appropriate size to meet the needs of drug separation. Using the company's precise manufacturing technology, the particle size of the nano-microspheres can be directly controlled, and 90% of the microspheres produced can be used directly, so it has a higher manufacturing cost advantage." Jiang Biwang told Hay Think.

“Previously, a European pharmaceutical company used 13,000 liters of fillers for drug separation and purification from a Japanese company. After Nanomicro developed a fine monodisperse filler, it replaced 13,000 liters of Japanese company`s fillers with only 3,000 liters. SZNW innovative product The excellent performance shocked European pharmaceutical companies and Japanese filler suppliers.

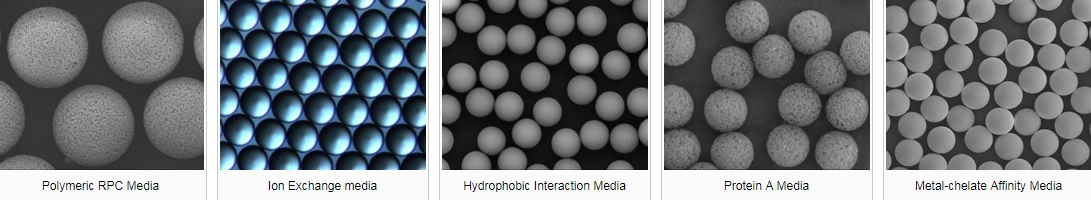

The high performance monodispersed microsphere products include:

Silica Chromatographic media (Silica Gel)

Polymeric Chromatographic media

Ion Exchange Chromatographic Media

Hydrophobic Interaction Chromatographic Media

Protein A Affinity Media

Gel Permeation Chromatography Media

Carbohydrate Analysis Media

Prepacked HPLC columns

Solid Phase Extraction Sorbents

Polystyrene Particle Size Standards

Silica Particle Size Standards

Magnetic Microspheres

Polymer Spacers

Silica Spacers

Nickel-plated Resin Microspheres

Gold-plated Resin Microspheres

Light Diffusing Microspheres

Latex Particles

…

Chromatography Media

SZNW produces the most complete range of monodisperse chromatographic media and SPE sorbents based on acrylic polymers, polystyrene or silica. The spherical and monodisperse sorbents with precisely controlled uniform particle size, optimized pore structure and surface functionalization provide high resolution, excellent selectivity, low back pressure , high recovery yield, and exceptional batch-to-batch reproducibility. SZWN is one of the few companies having capability to manufacture both Polymer and silica based chromatography media for reversed phase, normal phase, ion exchange, hydrophobic interaction, affinity and Protein A affinity chromatographic separations. Both monodisperse non-porous and porous (100 Å, 300 Å, 500 Å, 1000 Å) media with a size selection as small as 1.7μm for UPLC, and as large as 100μm for process-scale chromatography, are available from SZNW.

LCD Spacer

SZNW provides a complete line of high quality resin and silica spacers wiith precisely control the particle size, particle size distribution, hardness and surface characteristics. NM Spacers composed of highly crosslinked polymer or silica have very tight particle size distribution, and excellent resistance against heat, cold and chemicals.

Conductive Microspheres

SZNW provides high quality nickel-plated resin particles and gold-plated resin particles for microelectronic interconnection. These electrically conductive particles are dispersed in an adhesive binder as anisotropic conductive film (ACF) or anisotropic conductive paste (ACP) employed in the LCD assembly process. SZNW's conductive products have outstanding size uniformity, high conductivity, appropriate elasticity and strong adhesion between the metal layer and the resin core. The products are designed for fine pitch electrode coupling in electronic products such as COG and used for vertical conduction between two glass plates on LCD panel.

Magnetic Particles

SZNW provides a series of magnetic particles with narrow size distribution and super-paramagnetism. These small magnetic particles have a resin core and an iron oxide layer sandwiched between the core and an outermost layer. The outermost layer of the particles is inorganic SiO2 or a functionalized polymer which completely covers iron oxide to prevent it from potentially incompatible interaction with biomaterials. These magnetic particles have a very good dispersity with well controlled particle size and narrow particle size distribution.

Particle Size Standard

SZNW supplies a full range of size standard microspheres based on both silica and polystyrene. All of them are determined by Coulter Counter, DPS Disk Centrifuge, Dynamic Light Scattering, TEM, SEM, and Optical Microscope against Standard Reference Materials (SRMs) from the National Institute of Standards and Technology, US Department of Commerce(NIST). The particle sizes of these microspheres are therefore traceable to globally recognized primary standards of NIST SRMs.

Customer Reference