Founded in 200, SHXS Semiconductor Materials Technology Group is a leading 300mm (12-inch) semiconductor silicon wafer technology company in China.

Semiconductor silicon wafers are the food of the integrated circuit industry. 90% of integrated circuits are manufactured on silicon wafers. They are the most important and most basic integrated circuit material. At present, 300mm silicon wafers have become the mainstream material for chip manufacturing, and the use ratio exceeds 70%. In the past, China's 300mm semiconductor wafers were 100% dependent on imports, which became the main bottleneck for the construction and development of my country's integrated circuit industry chain.

In order to realize the national strategy of independent and controllable 300mm semiconductor silicon wafers, SHXS has undertaken and has fully completed the national 02 major scientific and technological task of "300mm silicon wafer technology research and development at 40-28nm technology node", and undertook the "20-14nm 300mm silicon wafer" "Complete technology research and development and industrialization" special task. The company's 300mm silicon wafer products can be widely used in integrated circuit industries such as memory chips, logic chips, analog chips, IGBT power devices, and communication chips.

SHXS has completed the first phase of 150,000 pieces/month production target, and achieved sales of more than 1.7 million pieces. The production capacity of 300,000 pieces/month in the second phase of construction will be reached by the end of 2021, and the scale effect of production capacity will be formed by then. In order to fully meet the urgent needs of China's integrated circuit industry for silicon substrate materials, solve the problem of independent controllability of large silicon wafers, and achieve the ultimate goal of 1 million pieces/month production capacity.

SHXS actively provides silicon wafers to the international market, and provides high-quality products in accordance with customer requirements. From wafer pulling, slicing, grinding, polishing, cleaning, and finally to packaging, the entire production process strictly follows quality standards, so Customers can be trusted. The main products are 300mm polished wafers, epitaxial wafers and test wafers.

Products

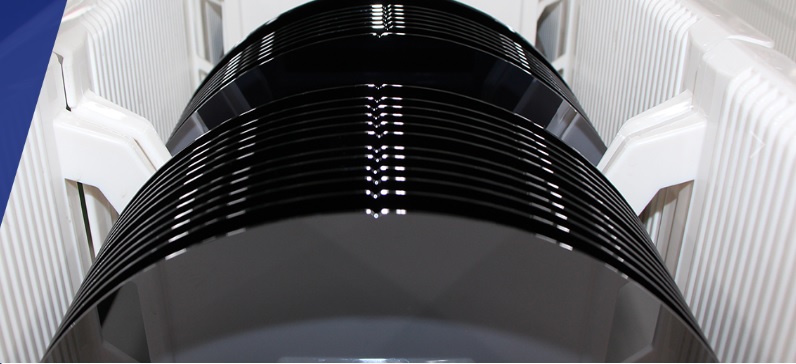

300mm Epitaxial Wafer

A substrate wafer with a single crystal thin film formed by epitaxial growth is generally called an epitaxial wafer. The growth of crystals is carried out on the substrate by the method of vapor phase epitaxial deposition, which is aligned with the crystal surface of the bottom substrate for growth. Epitaxial silicon wafers are widely used in diodes, IGBT power devices, low-power digital and analog integrated circuits, and mobile computing communication chips. SHXS also provides different types of doped epitaxial wafers, N-type or P-type, etc. according to customer requirements.

300mm Polished Wafer

The 300mm polished wafer is a wafer of high-purity silicon (Silicon). After the monocrystalline silicon ingot is produced, the cylindrical monocrystalline silicon of the ingot is cut into thin slices. Usually widely used in power devices, digital and analog integrated circuits and memory chips. The company also accepts customers' different conditions and manufactures high-quality silicon wafers that meet customer needs.

300mm Test Wafer

Test Wafer is mainly used for experiments and inspections. In the early days of the manufacturing equipment being put into use, Test wafers were also used extensively to improve equipment stability. Because the purpose of use is different from the commonly used wafer products, the recycled wafers in Test Wafer are commonly used.