BJAT Tungsten and Molybdenum Technology Group is a wholly-owned subsidiary of China's listed company BJAT Advanced Materials Technology Group. It is composed of two leading companies in the field of deep processing of tungsten and molybdenum materials in China, "BJTL Tungsten and Molybdenum Technology Group" and "BJAT Refractory Materials Branch" Merged.

The headquarter and R&D center of the group are located in Beijing, with 3 manufacturing bases in Tianjin, Shaanxi and Shandong, with a total area of more than 600 Mu.

BJAT's main business is advanced metal materials, serving strategic emerging industries, and providing advanced metal materials, products and solutions to high-end customers around the world.

The high-performance refractory metal materials and products such as tungsten, molybdenum, tantalum, niobium, rhenium, etc. developed and manufactured by BJAT are not only widely used in aerospace, defense and military industry, automobiles, electronic power, equipment manufacturing, metal material processing, quartz, glass and glass Fiber manufacturing, high-temperature industrial furnaces, electric light sources and other traditional industries are also widely used in various emerging industries such as liquid crystal display, solar energy, nuclear energy, nuclear medicine, LED lighting, large-scale integrated circuits, new energy vehicles, and consumer electronics.

BJAT is a world-class manufacturer and solution provider of advanced tungsten and molybdenum materials and high-end products.

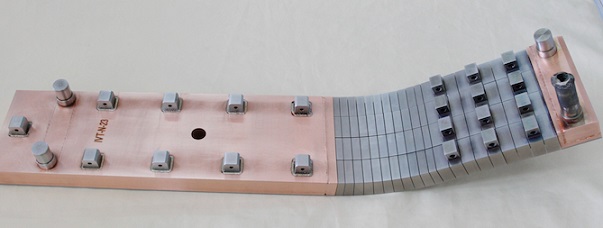

Tungsten matrix high-density alloy nuclear power flywheel and thrust plate

AP1000 upper and lower flywheel: The tungsten-based high specific gravity alloy developed by BJAT is used in the main pump of the cooling system of the 3rd generation + nuclear power plant. Because of its high density and performance, the device is used as the main pump of the nuclear power cooling system after precision machining Inertial flywheel, in order to ensure that the main pump system can continue to work and cool the nuclear power plant to avoid accidents when the nuclear power plant suddenly fails.

BJAT and Chinese nuclear power related units used hot isostatic pressing powder-solid diffusion connection technology for the first time in China to prepare AP/CAP thrust discs. The project solved a series of technical problems such as high-purity hard layer powder, large-scale hot isostatic pressing technology, powder-solid diffusion connection technology, etc., and produced a large-scale composite thrust plate.

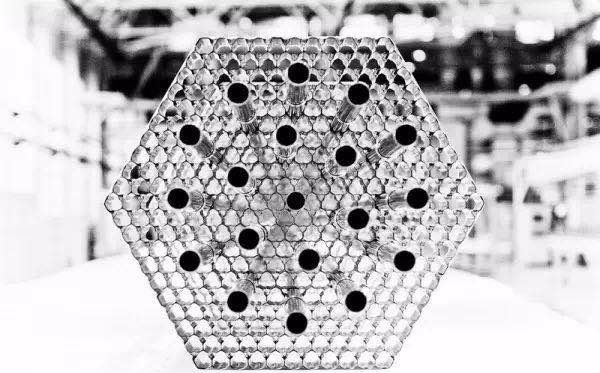

Aluminum matrix boron carbide neutron absorption plate

Aluminum-based boron carbide: Boron carbide has low density and high hardness. Its isotope 10B has a high thermal neutron capture cross-section and is free of secondary corrosion pollution. It is a commonly used neutron absorption material. Aluminum and aluminum alloy are light in material and similar in density to boron carbide. Aluminum-based boron carbide combines the advantages of aluminum and boron carbide, and has good mechanical properties and thermal neutron absorption performance. It can provide a series of neutron absorbing materials, including plates, rods and tubes, with an annual output of 300 tons.

Tungsten and molybdenum materials for ITER fusion reactor

The International Thermonuclear Experimental Reactor (International Thermonuclear Experimental Reactor) is a superconducting tokmak capable of producing large-scale nuclear fusion reactions. The plasma ring is in the ring-shaped sheath of the shielding cladding. The shielding cladding will absorb 500,000 kilowatts of thermal power and all neutrons produced by the nuclear fusion reaction. Therefore, a material resistant to high temperature and high heat is required as the first wall material facing the plasma. The WCu composite parts and TZM materials produced by BJAT can be used as key materials for plasma.

Inconel718 for nuclear power fuel rod assembly

AP1000 Tungsten Control Rod: The tungsten control rod assembly has low reactivity value. The use of mechanical methods can provide relatively small reactivity adjustments for the reactor, thereby reducing the use of chemical and volume control systems to adjust the boron concentration of the reactor coolant. Therefore, the daily treatment of reactor wastewater can be significantly reduced, and the design and operation of chemical and volume control systems can be simplified. In the process of base load and load tracking, the gray control rod assembly can be automatically repositioned to maintain the average coolant temperature controlled by the program. Lifting or inserting the ash control rod assembly can also effectively compensate for the effects of fuel and combustible poison burnup, power and temperature changes, and changes in core xenon conditions on reactivity.