On March 12, using the metal forming technology developed by theSDYL Energy Equipment Tech Group, the world's largest welded integral stainless steel ring forging was successfully rolled.

The ring has a diameter of 15.6 meters and a weight of 150 tons. It has achieved the 100-ton class metal billet grading and forming for the first time. This is also the world's largest forged stainless steel ring with the largest diameter and weight.

Under the entrustment and support of the China Nuclear Group, where the Chinese Academy of Sciences Metals is located, an industry-academia-research team was formed to apply TG's high-purity continuous casting slabs and developed a ring-shaped forging with a diameter of 15.6 meters at SDYL Energy Equipment Tech Group. High degree of organization and good uniformity. The giant ring will be used in China's fourth-generation nuclear power units, and its successful development will effectively guarantee the implementation of major equipment in China's nuclear industry.

As the support ring of the core components of the fourth-generation nuclear power unit in China, not only the pressure vessel boundary and safety barrier, but also the weight of 7,000 tons in structure, it is the "backbone" of the entire reactor. In the past, such giant forgings were manufactured by multi-section billet welding in foreign countries, which not only had long processing cycles and high costs, but also had weak structural properties of the material at the weld location, which posed a hidden safety hazard to the operation of nuclear power plants.

After more than ten years of hard work, the researchers from the Institute of Metal Research of the Chinese Academy of Sciences have developed original metal forming technology and revealed the healing mechanism and structure evolution mechanism of the building interface. It has broken through the limitation of the idea of “making big by big” for large forgings and developed A series of key technologies such as surface activation, vacuum encapsulation, multi-directional forging, hierarchical construction, and integral ring rolling have completely eliminated the interface between multiple layers of metal, making the position of the interface of the support ring forgings completely consistent with the base metal in composition, organization, and performance. , To achieve a "small to large" new processing and manufacturing, greatly improving quality while reducing manufacturing costs.

This technology has been evaluated by many academicians and experts as a transformative innovation in the field of large component manufacturing, and has been applied in the fields of hydropower, wind power, nuclear power and other fields. It has promoted the rapid development of high-end equipment in China and guaranteed the independent and controllable play of core materials of major equipment. Played an important role.

About SDYL Energy Equipment Tech Group

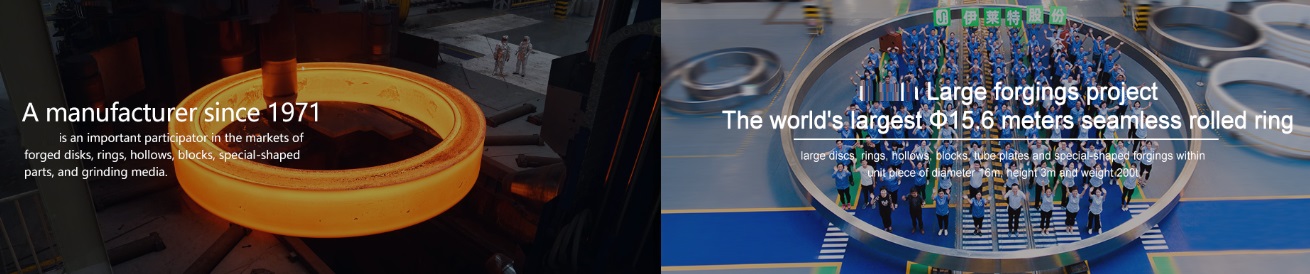

SDYL Energy Equipment Tech Group is a leading manufacturer specializes mainly in a diversified range of products within the forgings industry. Our main products include discs, rings, hollows and special-shaped forgings; grinding balls, rods and liners, mainly used in fields such as wind power, nuclear power, UHV, petrochemical, offshore engineering, machinery manufacturing, mining and other fields.

SDYL is in the leading position of clean energy, fossil energy, heavy equipment and mining industry including:

In the field of wind power, we are the main manufacturer of tower flanges in China, and provided tower flanges for DTC 10MW and GE 12MW;

Precision Forgings For Wind Turbine

Pipe Flange / Pylon Flange

Disc Forgings

Ring Forgings

Forged Hollows

Seamless Ring Rolling Forgings

Custom Forgings

In the field of nuclear power, we maintain a manufacturing record of diameter 15.6 meters in forging rings worldwide;

In the field of pipe flanges, we have more than 20 years of export experience, and obtained the certification of the eight countries classification society;

In the field of mine grinding, our export volume of forged grinding steel balls ranks among the top five in the industry;

Grinding Media

Rolled balls

Forged Balls

Casting Balls

Grinding Rod

SDYL's history can be traced back to 1971. now the group has 5 subsidiaries and one overseas manufacturing site, covering an area of 350,000 m2 and with 1,300 employees. For nearly half a century, It has always been steadfastly devoted to the forging industry. From offshore wind turbines on the Atlantic coast to the oil fields deep in the deserts of the Middle East, to mines in the lofty mountains of Peru, our products have made their mark. Adhering to the values of “honesty, humility, perseverance and work ", SDYL is committed to creating sustainable value for global customers through high-quality products.

Certifications