BJAT Environmental Engineering Technology Co., Ltd., was founded in 2015, is merged by former Filtration Mate-rials Branch and Engineering Technology Division controlled by Chinese BJAT Advanced Technology & Materials Co., Ltd.,

BJAT has set up three business segments, including Industrial Filtration & Purification, Clean Energy Engineering and Advanced Intelligent Manufacturing, which covering:R&D and manufacturing of advanced porous materials and components, developing filtration, separation, concentration and coalescence technologies in gas-liquid-solid three phase, as well as designing and producing its integrated equipment; projectdesign and general contracting in areas of clean energy, clean and comprehensive utilization of coal, sulfur recovery, environmental protection & resources recycling, hydrogen energy utilization, VOCs treatment and so on; and developing new processing technology for advanced materials, designing and integrating its equipment, as well as building digital factory.

Focusing on energy cleaning utilization and clean energy technology, BJAT is an integrated Environmental Pollution Control Service Provider with full competency of product R&D and manufacturing, equipment matching, system integration, engineering design and general contracting, aimed to realize clean process, emission reduction& harmless treatment , and resources recycling in industrial fields.

INDUSTRIAL FILTRATION & PURIFICATION

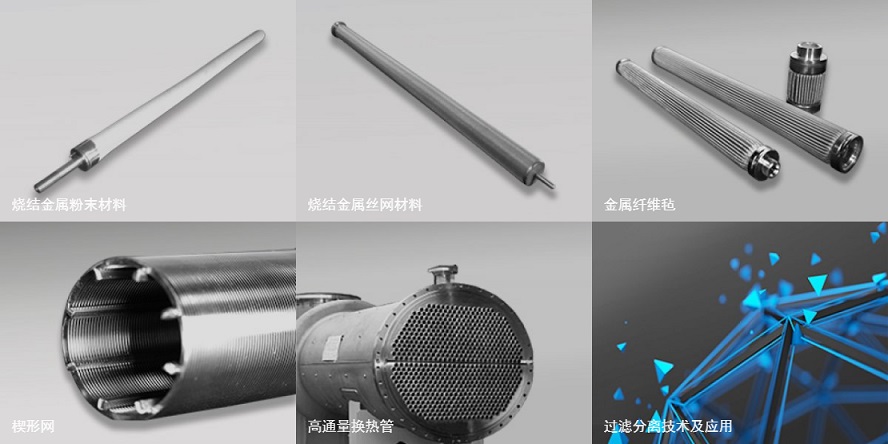

Sintered Metal Powder Material and Filter Elements

FeAl Series

FeAl porous materials, a kind of porous material, is sintered after compression molding of pre-alloyed FeAl powder. As an Intermetallic compound, it takes into account the mechanical properties of metals and the corrosion resistance of ceramics, with stronger sulfur corrosion resistance than metals and higher mechanical strength and thermal shock resistance than ceramics. Therefore, it is widely used in the circumstances such as filtration and purification in high-temperature sulfur containing environment, for example, Fly Ash filters in Shell coal gasification and char filters in EGSA coal gasification .

Stainless Steel Series

Stainless steel is a common metal material resistant to air, water and other corrosion. Stainless steel porous material is a kind of porous material, which is sintered after compression molding by stainless steel alloy powder with good heat resistance and corrosion resistance. It is widely used in gas-solid, liquid-solid separation and fluidization distribution in the fields of petrochemical, coal chemical, food, medicine and so on. The products such as adsorption desulfurization filter of SZorb, raw oil filter, residue filter, oil slurry filter and aeration cone are included.

Superalloy Series

Superalloy is a metal material based on iron, nickel and cobalt, which can work for a long time above 600℃ with certain stress. With the performance of excellent high-temperature strength, good oxidation and thermal corrosion resistance, comprehensive performance of stainless steel, such as fatigue resistance and fracture toughness, superalloy is mainly applied to gas filtration, powder recycling under the high temperature, such as high-density ethylene catalyst filter.

High flux metal membrane

High flux metal membrane is compound porous material of wire mesh or metal fiber felt and metal powder. It makes full use of the toughness and flux of the support layer of wire mesh, and combined with the high-precision film of surface metal powder to form a high-flux, high-precision compound porous material with high-temperature and corrosion resistance. It has a wide range of application in the field of high-flux and low-resistance high-temperature gas dedusting, which is an ideal substitute for organic baghouse dedusting and electrostatic precipitator.

Sintered Metal Mesh Material and Filter Elements

Sintered Metal Mesh Porous Materials and Its Filter Elements are made by multi-layers of metal woven mesh through the process of special lamination design and vacuum press sintering.

Sintered Metal Fiber Material and Filter Elements

Sintered Metal Fiber Material and Filter Elements are made of μm-level metal fibers with non-woven pavement through layering and high temperature sintering.

Wedge Wire Screen and Filter Elements

Wedge Wire Screen/Johnson Screen and Filter Elements are made by winding the special wedge-shaped stainless wires (winding bars) on a group of longitudinal supporting rods (bar supporting rods) arranged in cycle through welding.

Sintered High Flux Tubes for Heat Exchange

Sintered High Flux Tubes for Heat Exchange could significantly reduce designed heat exchanging area, reduce equipment volume and save project investment.

HPHT Fly Ash Filter

-Manufactured by BJAT`s self-patented material Fe3Al with unique blowback structure and special designed tubesheet, succeeded in replacing ceramic candles with its excellent anti-cracking property

-Widely used in process of Shell, U-gas, KBR, etc..

Application: filtration and dust removal for synthesizer in coal gasification and lignite extraction process

…