SHGL Automation Technology Co.,Ltd. is a leading provider of intelligent flexible loop line with direct driver and magnetic levitation technology solutions.

It focuses on the automation of intelligent manufacturing, maintains the spirit of technology innovation, user orientation, excellence, open cooperation and efficient services.

It has established the advantages of precision, high speed, intelligence and easy to use solutions in the field of intelligent manufacturing, providing competitive intelligent flexible high-speed line solutions, products and services for equipment manufacturers, manufacturing users and partners. It is committed to improving the global quality and efficiency of China and global manufacturing industry to reach the world-class level and move towards the rapid development goal.

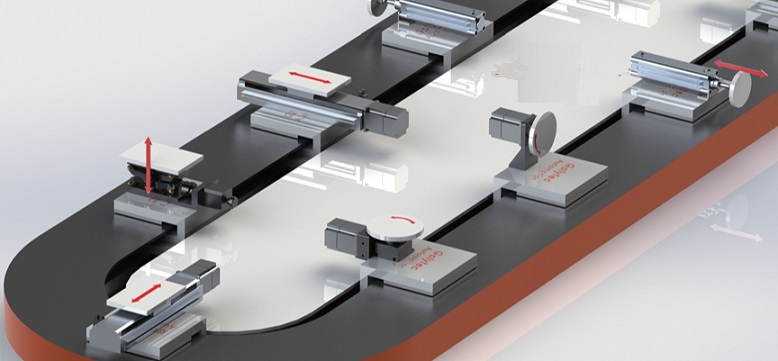

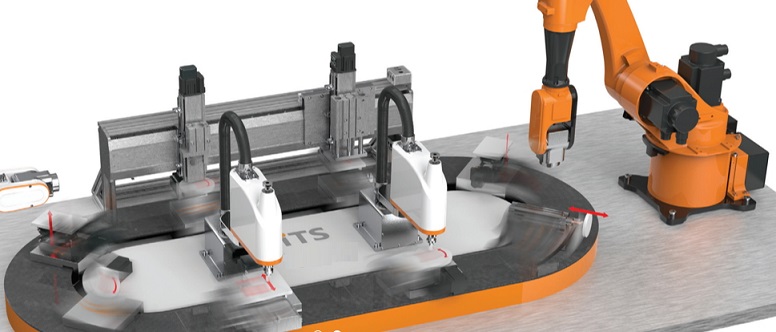

As a general-purpose infrastructure of the manufacturing industry, the ring transmission line has now entered the iterative period of the third-generation product-the moving iron direct drive servo system. The first two generations are composed of chain/friction transmission (screw, cam) and rotary servo system. They belong to the traditional equipment transmission line. Due to the low degree of automation, high energy consumption, low speed, low precision, and long design and manufacturing cycle, they have It is difficult to meet the demand for intelligent upgrading of the manufacturing industry, and cannot effectively support flexible manufacturing and high-precision application scenarios. This has also become the main problem to be solved by the third-generation ring transmission line.

Intelligent Transport System

SHGL’s CTO Chi Feng stated that the company has implemented an ironless direct-drive flexible ring-shaped transmission line on the technical route. Compared with another technical route with an iron core, it has a higher repeatability positioning accuracy, and the transmission line The dynamic smoothness, followability and other indicators can be improved several times. In addition, the transmission line can be docked with the software to read the measurement equipment data on the mover, which is used to adapt to the production applications of different processes and non-fixed beats, so as to cooperate with flexible manufacturing, small batches, and multi-variety production, supporting industrial big data transmission and reducing Upgrade cost.

Because SHGL adopts ironless direct drive flexible ring transmission line technology, there is no suitable software and hardware at home and abroad, so the company adopts a completely self-developed method. The product was in the state of low-volume production in the first two years, and has cooperated with about 30 customers, including major customers in 3CLCD panels, electric vehicles, automotive electronics, packaging and printing, medical and other industries. The cumulative shipment volume is nearly one kilometer. It will enter the mass production stage starting next year.

In terms of price, the third-generation flexible toroidal transmission line is higher than the traditional old equipment, but because most factories are still using traditional equipment, the demand for replacement is strong, and the price of SHGL products is lower than similar overseas products. The response speed has a certain local advantage over overseas manufacturers, and the production efficiency of customers has increased several times after deployment. With standardized products, SHGL will expand its production scale and expand its application scenarios through direct sales and channels. The company expects its revenue to achieve an average annual growth rate of 2 times in the next three years.

From the perspective of the overall market trend, flexible wires are currently in the blue ocean market, and their share of automated production lines in Europe and the United States has begun to rise rapidly, with an annual growth rate of more than 20%, mainly with iron cores, such as Beckhoff, B&R, Rockwell ; China's flexible line has a relatively low share of automated production lines, and the gap with Europe and the United States is obvious. The future market size is tens of billions of yuan, with great potential.

The SHGL core team has an average of 10 years of R&D experience. CTO Chi Feng is an engineering doctoral student in the Department of Mechanical Engineering of Tsinghua University. He has served as the head of the "Eleventh Five-Year Plan" National 02 Major Special Semiconductor Equipment Project, "Very Large Scale Integrated Circuit High Resolution Laser Interferometer and Vacuum Manipulator Research" Shanghai Science and Technology Commission Project The person in charge, the project leader of "Nano-level positioning accuracy three-axis planar motor and drive system" Shanghai Science and Technology Commission, "Nano-precision multi-degree-of-freedom motion system key technology and its application" won the 2012 National Technical Invention Second Class issued by the State Council prize.