As the world's largest manufacturer of photovoltaic modules, China is naturally also the world's largest demand country for supporting raw materials for photovoltaic modules. For a long period of time, some key raw materials are mainly dependent on imports. In recent years, the comprehensive localization of the photovoltaic industry has also driven the development of upstream raw materials. Among them, the fluorine film for photovoltaic backplanes is forming an industrial layout in China, and some technology companies have even achieved mass production, stirring the global market.

HZFM Film Material Technology Group, a Chinese film material high-tech enterprise founded by overseas technical Technical experts returning home, is one of them. At the 2018 "Quality Wins China" Photovoltaic Ceremony hosted by TüV Rheinland in Wuxi, Jiangsu Province, Hay Think was fortunate to interview this technology that "breaks the monopoly of fluorine film imports and ranks No. 1 in the world in PVDF film shipments for two consecutive years" Wang Peigang, CTO of a growing company. He confidently stated that in the past 8 years, HZFM has focused on "doing a good job of photovoltaic protective film", and the future struggle is to temper it into a golden sign.

HZFM became a spoiler in the photovoltaic protective film industry: cost reduction by 80% and win back domestic and foreign markets

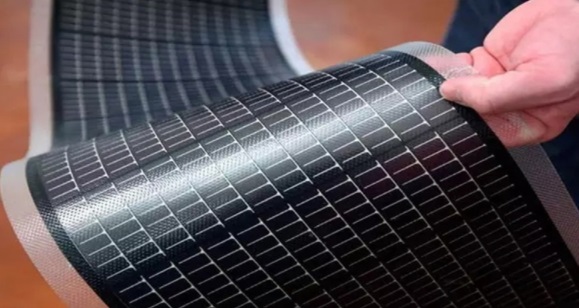

At present, the global market's budget model for photovoltaic modules is based on a 25-year life cycle. How to ensure that the photovoltaic modules can not only absorb solar energy efficiently, but also withstand the intense heat of the midsummer sun, resist the wind and sand in the desert area, and prevent water vapor penetration and corrosion for nearly a quarter of a century? The key role of the protective film is highlighted.

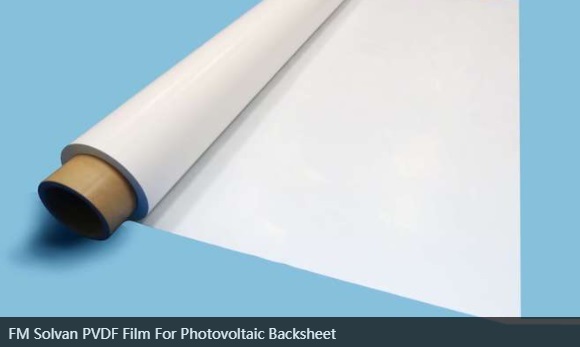

Wang Peigang made a vivid analogy: if polysilicon is the heart of photovoltaic modules, the backplane is equivalent to its armor, and the outermost protective film is its body armor. Although the protective film accounts for a small proportion of the cost of photovoltaic modules, its functional requirements for UV aging resistance, chemical corrosion resistance and wear resistance directly determine the service life of photovoltaic modules. From the perspective of quality protection, the fluorine-containing film is several orders of magnitude higher than the fluorine-free film in the combustion index. The current use of fluorine film as a photovoltaic backplane protective film has been unanimously recognized by the industry.

However, such vital raw materials for photovoltaic modules were previously monopolized by foreign chemical giants such as the United States, France, South Korea and Japan. Most Chinese companies rely on imports, and high prices have affected China`s photovoltaic manufacturing costs. According to Wang Peigang, before 2008, only DuPont in the United States made fluorine film for solar photovoltaic. Due to the large brand effect and technology monopoly, the price at that time remained high. Later, the French company Arkema developed the PVDF film. Although the price of DuPont was lowered, the price reduction was still not large.

Until 2010, the fluorine film market structure has undergone tremendous changes. That year, Dr. Gu Fangming, the founder of HZFM, returned to China from overseas to start his own business. He and his team spent nearly two and a half years on research and successfully developed the PVDF film for solar photovoltaic cell backplanes in 2013. This product based on completely independent intellectual property rights technology and processing technology has realized the mass production of China's first commercial fluorine film.

Since opening the "gate" to the localization of photovoltaic fluorine films, HZFM has released amazing production capacity,

In 2011,HZFM realized the localization of PVDF films for Photovoltaic applications and closely following DuPont of the United States for three years.

In 2016, It surpassed DuPont in one fell swoop to become the world's largest supplier of protective materials for Photovoltaic panels, with annual output of 200 million squaremeters.

and finally achieved its goal of No. 1 in production capacity in the world for two consecutive years in 2016 and 2017. The most striking thing is that its scale effect has made the price of fluorine films achieve amazing changes. With the competition of Chinese enterprises, the price of fluorine membranes of the same area is nearly 80% cheaper.

So far, China's domestically produced fluorine films have not only won back a large part of the domestic market, but have also begun to "harvest" foreign markets. "As time advances, I believe that the market share of domestic fluorine membranes will definitely continue to change, and the cost-effectiveness of domestic films will make localization more and more common." Wang Peigang said proudly.

In 2015, HZFM realized the production of transparent PVDF film which offers alternative to dual-sided power generation and light component ETFE.

Trailblazer: Technological innovation tempers big brands and strives to be the world's first

The continuous expansion of the global photovoltaic industry has also brought profound changes to the upstream demand for fluorine film. It is understood that the global new installed capacity of photovoltaic power generation is growing rapidly at an annual growth rate of about 15%. It is expected that the global average annual new installed capacity will reach more than 100 GW before 2030. Based on this calculation, 1.3 billion square meters of PVDF film will be needed in the future. According to the estimated unit price of about 4-6 yuan per square meter at that time, fluorine membrane companies will usher in a market of nearly 10 billion yuan each year.

As the spoiler of the global fluorine films industry and the pioneer of domestic mass production, in the face of such a huge growth prospect in the future, HZFM's competitiveness is obviously more than price advantage. From a commercial point of view, the target of brand effect is higher added value and bargaining power. To build a world-renowned big brand in the field of photovoltaic backsheet fluorine film is its future dream and direction. In this regard, Wang Peigang deeply feels: “We can only cultivate a classic brand by providing customers with more reliable technical solutions through excellent technical precipitation, and gaining the trust of customers.”

The current popular technical solutions are essentially a deep and thorough understanding of the market, and then provide customized services according to the needs of end customers. This concept is also applicable in the photovoltaic industry. For example, according to different geographical environments, customers will put forward different requirements for fluorine filmsmaterials. In China alone, different regions have strict requirements on which material to choose; to provide customers with an in-depth product, not the higher the performance, the better Excessive performance will increase the cost of customers; in foreign countries, customers not only pay attention to quality, but also pursue aesthetics… The above all involve product personalization and require different technical solutions.

Wang Peigang said that in order to follow the market layout, HZFM has been updating its products in the past two years. For example, in the field of color, for domestic photovoltaic fluorine film, some fine-tuning will be made on the basis of milky white film; and for overseas markets such as Europe, America, Japan, India and Southeast Asia, it will also be adjusted to dark gray, black, dark blue, and transparent. , To meet the individual pursuit of customers.

To understand the market is to do well in the present, and to lead the market is to focus on the future. Companies that love technological innovation will take the lead in the face of new market opportunities and occupy the commanding heights. However, the exploration of new technologies requires significant capital investment, as well as the risk of profit conversion rate.

"Don't worry about this. The head of HZFM is a technical expert. He himself attaches great importance to and encourages technological innovation. The company invests in R&D funds every year to account for no less than 3% to 4% of sales revenue." Wang Peigang revealed Once the company pays attention to the new development trend of the market and determines that it may be the future direction after investigation and discussion, it will make a "technical reserve". For some innovative or leading technical work, the team started layout very early. Opportunities are always reserved for those who are prepared, and the "technical reserve" mechanism will be reserved for HZFM's professional field of "world first" vision with hope.

"HZFM's status in the market today is also inseparable from the approval and strong support of third-party testing organizations. In 2011, while still in the laboratory stage, we began to cooperate with TüV Rheinland and produced the world's first TüV Rheinland certification. 11 micron PVDF film, so the market promotion is relatively smooth." Talking about the feeling of participating in the "Quality Wins China" photovoltaic festival, Wang Peigang praised the circle of friends in the entire photovoltaic industry chain. It is precisely because of everyone's recognition of its authority and impartiality that it gains such influence!