AHER is an innovative technology enterprise focusing on the research of nano-film, planar electric heating technology-related insulation and electric heating materials, production equipment and processes, providing technical support for domestic and foreign enterprises in the fields of home appliances, personal care, automobiles, electronic cigarettes, etc. And product electric heating solutions.

At present, the company has successfully developed and produced ultra-fast, energy-saving, miniaturized, and intelligent electronically controlled nano-film electric heating elements, integrated modules and electrical products. The heating system of traditional electrical products is converted in electric heating efficiency, real-time fast, miniaturized and convenient. The heating system of traditional electrical products has been significantly improved and innovated in terms of electric heating efficiency conversion, instantaneous speed, miniaturization and convenience.

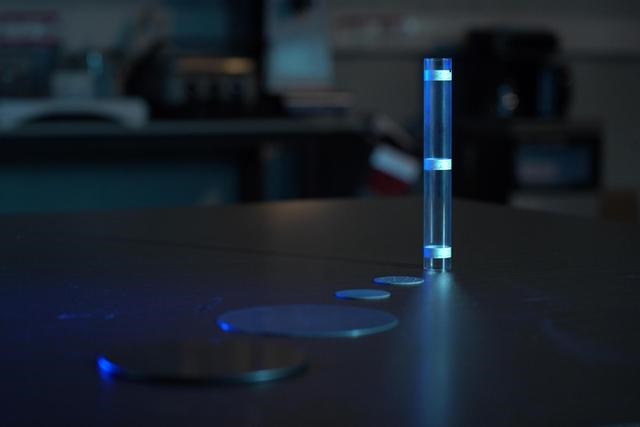

Nano film electric heating products

The cost of heating electrical products is generally concentrated on heating elements and control elements. The cost of the control components of heating appliances is gradually reduced due to the improvement of intelligence integration and the development of the semiconductor industry, but the heating components have not seen major breakthrough innovations in the past 100 years. At present, in addition to microwave and IE induced heat generation, most electrical products still use resistance wires for electric heating. "

The heating power density of the resistance wire is 8-15W/cm2, and it needs a certain preheating time to reach a stable working condition after power-on. The product structure that uses "resistance wire" as the heating element will have the opportunity to be gradually replaced by nano-film electric heating technology. The market size of household appliances alone is at the level of 100 billion yuan.

The nano-membrane heating element developed by AHER is essentially an electric heating technology. Compared with the traditional resistance wire heating element, the heating area of the nano-membrane heating element is equal to the heat transfer area, the heat conversion efficiency of the film is high, and the film can be miniaturized The design saves the space of the electric heating element and the corresponding matching materials. At present, the company's nano-film electric heating elements have four series: nano-film quartz and stainless steel flow-through electric heating tubes, nano-film electric heating sheets, nano-film electric heating cups and special-shaped customized products.

The principle of planar heating film technology has been around for a long time, but due to materials, processes and equipment, etc., there has not been a stable product for mass industrial production. The nano-technology invented by AHER is an advanced technology with the highest thermal efficiency, ultra-high power density and stable performance. AHER has carried out research and development and optimization on the coating process and equipment, using a variety of process combinations including surface treatment, electroplating, immersion plating, magnetron sputtering, and high temperature curing. The choice of substrates for nanomembrane products is relatively flexible and can effectively control costs.

According to the experimental data provided by AHER, the heating rate of the membrane surface reaches 50~150℃/s after power-on, and the power density is 5~170W/cm2. The film has low electromagnetic radiation, high electrothermal efficiency, can be plated on the surface of substrates of different shapes, and its volume is almost zero. The breakdown voltage of the membrane electric heating element on quartz exceeds 5000V, and the finished electric heating conversion efficiency reaches 92-98%.

Instant drinking water equipment is the first application market that AHER has entered. Current AHER customers include:

Joyoung, Supor, AUX, Philips, Yunmi, Beka, Haier, Nestle,Royalstar, Angel, Midea and other well-known home appliances brands.

Standardized nano-film electric heating elements and customized modules are on sale. The final products mainly include instant water dispensers, portable ultra-small water heaters, health pots, beverage machines, milk foaming machines, electric thermos mugs, car heaters, etc. .

In addition, AHER also conducts product research and development in the fields of ultra-fast steam generators, gas heating, automotive and air-conditioning thermal management, medical equipment, and industry.

At present, the company has more than 20 kinds of nano-film electric heating modules. The founder and CTO Dr. Hu holds a PhD in Stuttgart, Germany, and has many years of work experience as a technical executive in an overseas international multinational company. The company's R&D team are well-known technical experts in the home appliance industry, with many years of rich R&D experience and strong strength. The company has applied for more than 200 patents.

Judging from the market situation, the current electric heating technology and products dominated by resistance wire still occupy an absolutely large market share. With the development of nanomaterials, processes and supply chains, the application proportion of nano heating films will gradually increase.