The glass-ceramic, also known as glass-ceramic, refers to the basic glass with a specific composition of nucleating agent (or without nucleating agent), which is subject to crystallization heat treatment under a certain temperature system, and uniformly precipitates a large number of tiny crystals in the glass, forming a dense multiphase complex of microcrystalline phase and glass phase.

Transparent glass-ceramics, glass-ceramics with zero expansion coefficient, surface-strengthened glass-ceramics, different colors or machinable glass-ceramics can be obtained by controlling the type, quantity and size of microcrystals.

Ultra-low expansion glass-ceramics

seeing the name of a thing one thinks of its function

It has a coefficient of expansion of nearly zero, which means it can withstand extreme cold and heat without cracking and deformation

It is the material with the best dimensional stability in variable temperature environment at present, and is often used in extreme environmental conditions,

Such as space camera, photoelectric radar, astronomical telescope and other mirror materials

As the glass-ceramics break through the training, the grains become finer and more uniform with each promotion, and the mechanical properties are stronger.

Ultra-low expansion glass-ceramic refers to the glass with Li ₂ O, Al ⏴ O and SiO ₂ as the main components, which is formed with negative expansion after strict controlled crystallization treatment β- A composite material composed of quartz solid solution nanocrystalline phase and positive expansion glass phase has excellent optical, thermal and mechanical properties. The coefficient of thermal expansion (0~50 ℃) of the ultra-low expansion glass-ceramics in the Crystal Institute is 0 ± 0.2 × 10-6/℃。

The ultra-low expansion glass-ceramics developed by ZCRG have strong acid and alkali resistance, especially strong acid corrosion resistance.

The experiment shows that it takes more than 100 hours to put the ultra-low expansion glass-ceramics in 0.5 mol/L nitric acid with the corrosion thickness of 100 nm.

The microcrystalline material has small thermal expansion coefficient, compact structure, and the surface shape and roughness of the mirror after processing can be optimized, so it can be applied to the ultraviolet, visible and infrared multi-band space camera mirrors. Large-size microcrystalline materials are made by one-step molding, with relatively short manufacturing and processing cycles, high cost performance and low application risk. They are a kind of mirror materials with high cost performance. Therefore, many space optical imaging systems in the world use ultra-low expansion microcrystalline materials as space mirror materials.

in addition

In the inertial navigation system, glass-ceramics are used as the skeleton material of the laser gyro,It can effectively prevent gas leakage in the gyro cavity.

The working environment temperature of the laser gyro changes greatly (- 40~70 ℃). In order to ensure the working stability of the components, the smaller the thermal expansion coefficient of the materials used to manufacture the laser gyro cavity is, the better;

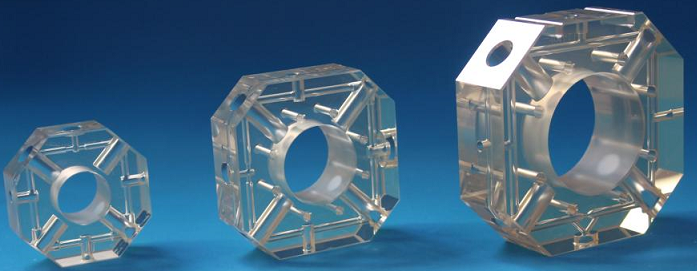

Ultra-low expansion microcrystalline cavity of laser gyro

In addition, the laser of laser gyro is generated by the electric excitation of helium and neon gas mixture enclosed in the laser gyro cavity. In order to avoid helium leakage and affect the gyro life, the cavity material helium permeability is also required to be very low.

The ultra-low expansion microcrystalline material is the material with the lowest thermal expansion coefficient and the helium permeability is also extremely low. These excellent characteristics make the ultra-low expansion microcrystalline material an irreplaceable material for laser gyro cavity.