Metal 3D printing is currently the most exciting topic in the field of printing. From aircraft engine components to the manufacture of space satellite parts, metal 3D printing has become the focus of the topic.

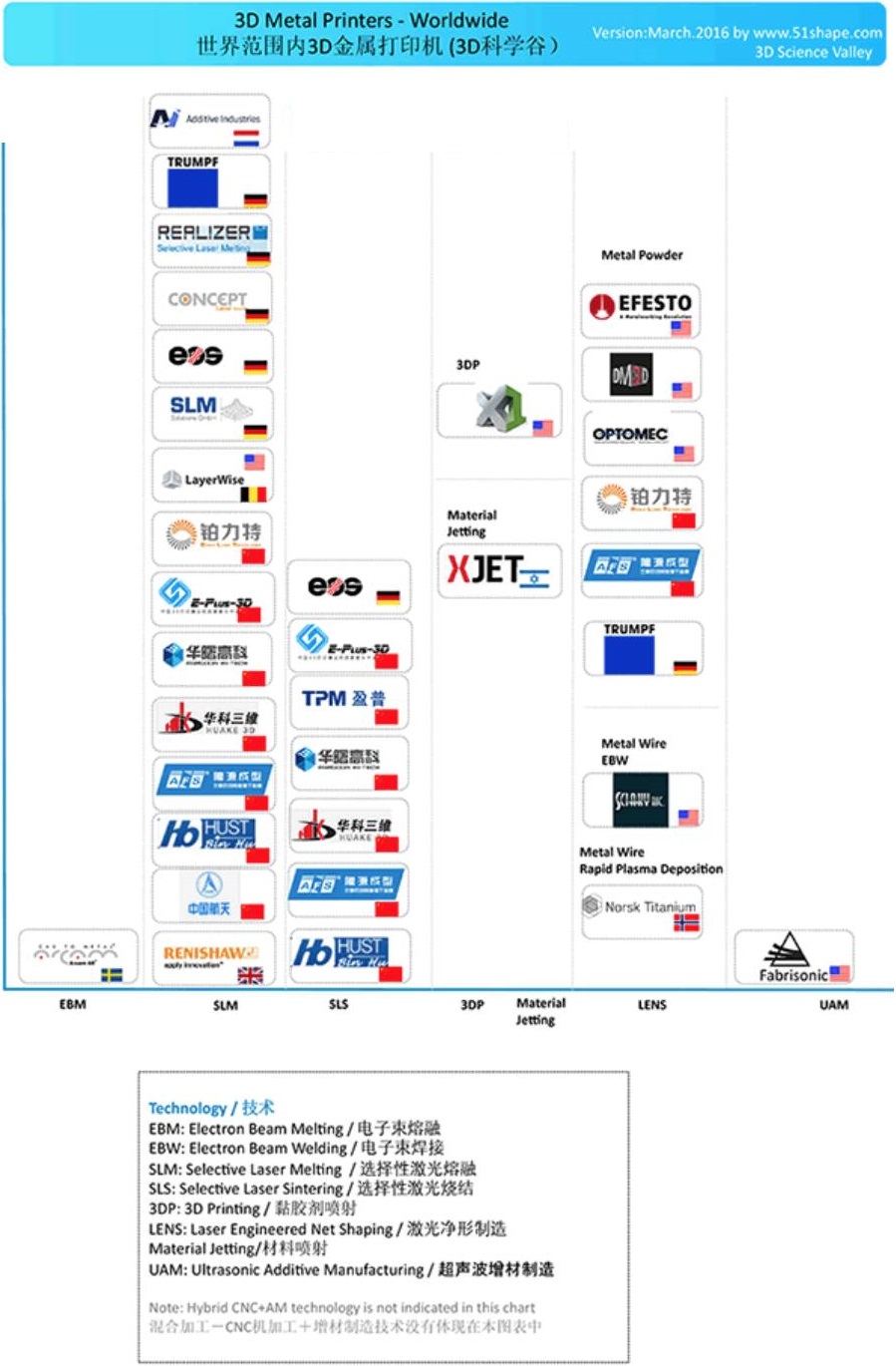

But the reality is that metal 3D printing is a broad concept, which includes very diverse technologies, which we usually do n’t distinguish but stack up together, even though they use different printing technologies and different metal materials ( Metal powder, wire or sheet metal). In this regard, through the 3D Science Valley matrix, one can understand the industry technology distribution characteristics and mainstream brands.

Patent expiration welcomes industry growth

To understand all aspects of metal 3D printing technology is a systematic project. Researchers at the famous American Oak Ridge National Laboratory (ORNL) have sorted out the "genealogy" of metal 3D printing in Tennessee: from the history of metal 3D printing Analysis of advantages, limitations and potential application trends of all major metal 3D printing technologies. The four technologies include powder bed sintering (SLS), powder bed melting (SLM, EBM), direct energy deposition (LENS), and binder spraying (3DP). ORNL also delved into the limitations of metal 3D printing compared to traditional manufacturing.

ORNL researchers believe that pure alloys and ceramic materials have significant development prospects. Recently, especially the application of high-temperature alloys including titanium alloys and nickel-based alloys in the field of metal 3D printing has continuously achieved breakthroughs. In terms of printing patents, although the core patents and subsidiary patents are foggy, 3D Scientific Valley believes that patents for domestic metal 3D printing equipment manufacturers are the top priority for enterprise development, but it is up to you to research and understand this market Every patent of a competitor and their hard work is undoubtedly almost impossible. On the one hand, you can learn more about the distribution of patents by entrusting an official institution similar to the Shanghai Patent Service Platform. On the other hand, you may wish to actively consult a professional patent lawyer to expire the core patents of competitors layout.

At the same time, various new 3D printing methods are also emerging: chemical vapor deposition (CVD, currently used for coatings), physical vapor deposition (PVD, using vacuum), 3D printing of liquid metal jets, and deposition in high-speed gas streams Cold spray technology for metal particles. These technologies have provided room for development of metal 3D printing technology to continue to differentiate.

Regarding the prospect of metal 3D printing, 3D Science Valley believes that compared to the future of metal 3D printing, we are still at the foot of the mountain. As patents expire and prices of heat sources such as lasers fall, this will help lower the price of metal 3D printing. With the large amount of R & D invested by major metal powder suppliers in metal materials, more new materials will emerge and a wider range of alloys will appear.

ORNL researchers believe that the average annual market growth of this technology will be about 18% by 2025, with the main driving demand coming from the aerospace, biomedical, and automotive industries, and the market size is expected to be $ 8.4 billion by 2025.

A more noteworthy trend is that the expiration of several patents may help the arrival of the era of open source, thereby greatly reducing the cost of metal 3D printing. 3D Science Valley learned the fact that researchers from Michigan Tech have already begun some interesting open source work.

The potential of metal 3D printing is opening up. By printing complex geometric shapes, reducing the number of components, and printing biocompatible products for the medical community, the significance of metal 3D printing is not the traditional cost reduction and efficiency improvement. It is to put product life benefits on an important agenda, reduce failure rates, reduce energy consumption, and improve reliability through product design. A better world that pays attention to efficiency in all aspects is coming.

Of course, although the prospects are bright, to move towards a wider application field, Scientific Grain believes that the technology of metal 3D printing has a lot of room for improvement and improvement, including achieving faster deposition rates, quality control in the process, reducing costs and production capacity And material expansion. At present, in terms of quality control, metal 3D printing lags far behind other production technologies, which is directly related to production costs and feasibility. Because of this reason, metal 3D printing cannot be promoted. However, bottlenecks also mean opportunities. The industry is anxious for the introduction of standards and protocols, and more efforts to predict and control print results through big data, including data measurement and monitoring technology, adequate material properties, modeling systems, Simulation systems, closed-loop control systems, etc.