SABIC today introduced two new radar absorbing LNP™ STAT-KON™ compounds for automotive radar sensors, significantly expanding its portfolio of these specialty materials. The new grades, based on polybutylene terephthalate (PBT) resin, may be used for integration with radomes manufactured using PBT material, which can provide superior resistance to automotive chemicals. They complement and extend SABIC's existing radar absorbing LNP STAT-KON compounds, which are based on polyetherimide (PEI) resin for withstanding higher processing temperatures or on polycarbonate (PC) resin for general applications that require high durability and a balance of physical properties. The high radio frequency (RF) absorption of these compounds can help increase detection range and improve signal resolution. Through materials innovation, SABIC is contributing to the growth of automotive radar and the design of next -generation sensors.

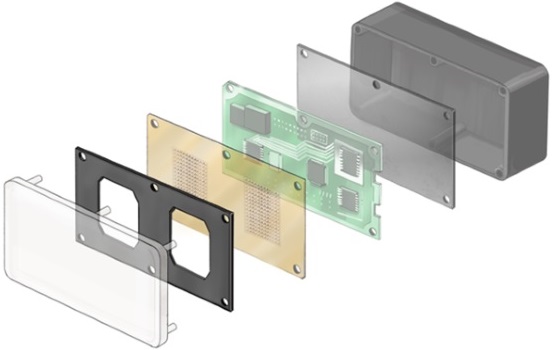

Radar sensors are widely used in advanced driver assistance systems (ADAS), where they provide capabilities such as blind spot detection, collision avoidance, automatic braking and traffic alerts. Radar absorbing materials (RAM) are used to shield the field of radar wave transmission and attenuate side waves that can cause ghost images or trigger false actions or alarms. A broader choice of radar absorbing LNP STAT-KON compounds can help manufacturers to increase flexibility in sensor positioning and function and to help design sensors that can be optimized for vehicle size and other variables.

“Radar sensors are a critical component of the ADAS suite, in part because they can operate in conditions such as poor visibility that impair LiDAR and camera functioning,” said Jeff Xu, LNP™ Product Manager, SABIC. “To support technology advancement in the radar sensor market, which is rapidly growing, SABIC continues to develop specialty materials that can enhance sensor accuracy and reliability. Our growing portfolio of LNP compounds offers high absorption of radar waves as well as potential cost benefits compared to radar absorbing materials designed for military applications ."

SUPPORTING GLOBAL GROWTH OF AUTOMOTIVE RADAR

The automotive radar market is forecasted to reach $12.16 billion USD by 2025, growing at a CAGR of 20.8%, according to Grand View Research, Inc.1 This rapid expansion can be attributed to increased investments in the automotive industry, higher vehicle sales, greater emphasis on safety and innovations in radar technologies. Novel materials are contributing to this growth trajectory by improving sensor performance. SABIC's new PBT-based LNP STAT-KON compounds deliver an RF absorption of 67 percent at 77GHz, which could allow for increased ADAS functionality for the automobile. To keep pace with rapid advancements in radar sensors, SABIC is developing additional grades that are either based on new resins or have higher radar absorbing properties.

SABIC offers extensive expertise in material development and a deep understanding of how radar units are designed and should perform in the automotive environment. The company also has access to innovative dielectric property tests and measurements in a wide range of frequencies, as well as modeling tools capable of performing simulations to help radar sensor manufacturers and automotive OEMs optimize system design and integration.

The complete line of SABIC`s radar absorbing LNP STAT-KON compounds is globally available.

About LNP™ STAT-KON™ COMPOUND

STAT-KON™ compounds contain electrically conductive additives that provide surface resistivity from antistatic, through conductive, to electromagnetic interference (EMI) shielding. Stat-Kon composites are rounded out by LNP's STAT-LOY™ and FARADEX™ compounds to provide a full range of electrically active materials.

Stat-Kon compounds offer cost-effective solutions when products must avoid static electricity buildup or discharge.

BROAD RANGE OF SURFACE RESISTIVITY Wide range of surface resistivity, from 100 to 1012 ohms/sq. (where non-treated base resins exhibit 1014-1018 ohms/sq.) Applications range from statically dissipative to electrically conductive.

CHOICE OF CONDUCTIVE ADDITIVES Can be formulated to meet specific needs with carbon fiber, stainless steel fiber, carbon powder, metal powder and flake, and migratory antistats. Depending on the electrically active filler or reinforcement, these compounds can suppress initial charges, minimize tribo charging from movement, insulate against leakage current, prevent electrostatic discharge to/from human contact, provide a grounding path for charge bleed-off.

FORMULATION BY APPLICATION Can be fine-tuned for surface resistivity, volume resistivity, static decay, and other engineering parameters.

BROAD RANGE OF ATTRIBUTES Broad range of mechanical, physical, and thermal properties depending on the base resin selected. The addition of other additives and reinforcements, including glass fiber, polytetrafluoroethylene (PTFE), and PTFE/silicone systems, further extend the properties. Many grades are also available as clean compound system (CCS) materials for applications requiring low levels of ionic contamination, particularly designed for the use in the disk drive industry.

DIMENSIONAL STABILITY Exhibit excellent isotropic shrinkage for dimensional stability and low warpage.

FLAME RETARDANCY Can be compounded for flame retardancy (FR), including non-halogenated FR compounds.

WIDE RANGE OF RESINS AND PROCESSING TYPES Available in most major engineering thermoplastics and in forms for extrusion, injection molding, thermoforming, blow molding, and rotational molding. Some series accept colors and aesthetic effects, and Stat-Kon can be formulated for cost-effectiveness .