Driving superior value through digital procurement

With emerging technologies and their applications, we hope that purchasing will create more value.

For enterprises, big data and advanced analytics will have a profound impact: taking data-driven decision-making to a new level, helping companies generate new insights and enabling them to collaborate on a large scale. Imagine that the purchasing team has deep connections with every level of its supplier base and has access to all relevant data on cost structure, availability, delivery cycle, finance, operational risk, and service and quality indicators. The purchasing team will be able to negotiate the “right” price, adjust their plans instantly, or switch to alternative suppliers in the event of a supply shortage. It can even help suppliers improve quality by proactively identifying problems and identifying their root causes more accurately. What category management manager will not be excited about having such a "tier one supplier X-ray" system?

Many CPOs that have applied more sophisticated business and demand leverage believe that big data and advanced analytics are key to improving procurement performance in the future. We have asked some CPOs around the world to quantify the near-term impact of digital procurement projects. On average, their expectations include a 40% annual cost savings, a 30% to 50% reduction in transaction procurement time, and a 50% reduction in value loss.

But CPOs are also asking which new digital solutions will bring real value to their companies. Among so many "digital purchasing" software vendors, which one can really deliver on its promises? What should their company's digital procurement roadmap look like?

Given the cross-functionality of the various data flows between the company and its partners, we hope that procurement will create value from many new applications in the future. Category managers can use historical and future spending data generated by a company's enterprise resource planning (ERP) and forecasting systems. The purchasing department receives product specifications provided by the engineering department, monitors contract compliance, invoice management and supplier performance, and generates supplier files and scorecards. Procurement also makes use of various external data sources such as supply market-specific commodity time series data, currency and inflation rates, tax and tariff data, or supplier solvency data.

But how does the procurement department discover and use this data to create real value? In the world of digital hype, new solutions enter the market every day. In this article, we try to introduce structure into the discussion and provide a simple framework for CPOs to think about superior value creation through digital procurement and advanced analytics. .

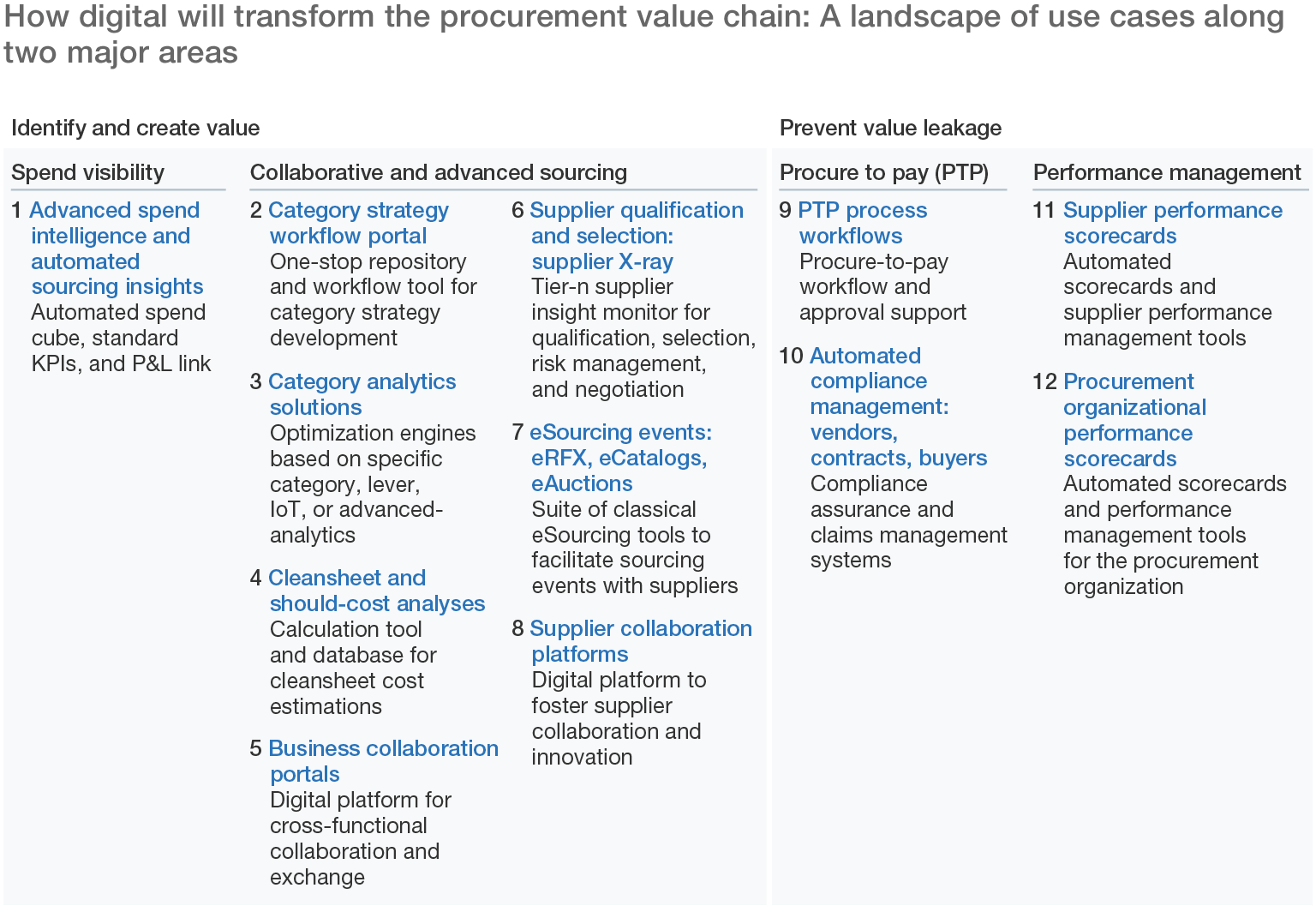

Digital applications that can truly change a company's purchasing performance fall into two broad areas:

1. Tools to identify and create value

2. Tools to prevent value leakage

Tools to identify and create value

In short, the tools to identify and create value support the strategic procurement process. They can be further divided into creating procurement spending visibility, and supporting advanced collaborative procurement.

Visibility of purchase expenditure

1. Advanced procurement spending information and automated procurement insights

The spending visibility tool starts with a solution that extracts historical purchase order (PO) and invoice data, and creates a purchasing spending cube. The prevalence of fragmented ERP systems means that many multinational and multi-company companies still struggle to build simple multidimensional databases of expenditures.

We expect existing solutions on the market to further enrich other data sources and include basic category-level key performance indicators (KPIs). For example, they will be able to generate automated price and specification benchmarks across entities, such as price arbitrage analysis or facility management costs per square meter and per person. The price will be linked to a material cost index or a product specification using linear performance pricing (LPP: Liner Performance Pricing). Category management managers will automatically generate visual chart dashboards and heat maps to help them identify and capture purchasing opportunities. Finally, by linking the spending cube solution in real time to company budget and profit and loss (P & L: Propfit & Loss) planning data, the next-generation system will help achieve a true transformation in procurement: you can track purchase expenditure savings directly in budget and profit and loss.

Collaboration and advanced procurement

2. Category strategic process portal

Although many systems support transaction procurement processes, few workflow solutions currently support the generation of comprehensive category strategies and system identification savings levers. Emerging solutions can guide category management managers through a configurable phased gating process, which includes every step of creating a category strategy: understanding demand, analyzing the market, creating savings and measuring the effectiveness of implementation. Relevant milestone meetings with cross-functional partners will be triggered automatically, and all ideas will be stored and tracked to final implementation steps.

These workflow solutions will allow teams to collaborate through shared file spaces, forums, chats, and video calls, and superiors will be able to track category management manager activities and their impact in real time. In addition, because they serve as a structured repository for all analysis and insights carried out during the strategy development process, these workflow systems will also almost automatically prepare the preparation of category strategy documents and business negotiations.

By applying today's state-of-the-art tools, we have seen the company reduce its category strategy development time by approximately 30%, while significantly increasing the insight and influence generated by the category management team. In a pilot project, the team's actual savings in procurement expenditures exceeded its initial target by an average of 20%.

3. Category analysis solution

Many of the more advanced category analyses today are very standardized: for example, LPP or Total Cost of Ownership (TCO) calculates a large number of similar parts, such as fasteners or motors. These analyses will increasingly be incorporated into standard applications. Once defined, these category solutions will periodically create pre-defined analysis activities and automatically mark the potential improvements and specific leverage needed to capture them.

In addition, we will see many category solutions for more complex data-intensive categories such as logistics, travel, communications, temporary labor or freight. These will be built on large, relatively standardized data sets, and once again allow a set of standard analyses to be performed to identify leverage and improvement potential. For example, freight optimization tools already work this way. They obtain routing data and complete pricing plans from multiple vendors to determine the lowest cost vendor mix. They can also suggest changes in demand, such as stopping courier delivery on Friday but ensuring delivery by next Monday. A large industrial company using a multivariable freight optimization solution can reduce its total air freight costs by 25%.

4. Reasonable Cost Analysis

Understanding the "should cost" of a part or service when producing with the highest efficiency and effectiveness is a key weapon in each buyer's negotiation with the supplier. The calculations used to calculate such costs also help identify savings opportunities from product design and value chain changes.

The tool includes a workflow application for constructing calculation tables, some professional tools for estimating different cost areas (such as processing, logistics, or indirect costs), and a set of databases (for example, labor costs) containing a library of templates and factor costs Rate, raw material index price and currency). It's not uncommon for these tools to reduce the cost of a product or service by up to 40%, while also reducing the time to market for new product designs.

5. Business collaboration portal platform

Early engagement with internal customers and cross-functional collaboration to jointly challenge requirements, specifications and processes are essential for good procurement. Digital platforms that promote communication, transparency and interaction can facilitate this collaboration. Many large software vendors have provided common collaboration spaces, including file repositories, collaborative workspaces, audio and video conferences, and calendars. We expect solutions that specifically address strategic procurement requirements. These include integrating requirements and regulatory data, as well as supplier insights, analysis, and strategies across different BUs and functions, allowing timely and effective interaction to challenge sources, locations, and methods.

6. Supplier qualification certification and selection: supplier "x-ray" scan

In the introduction of this article, we describe a scanning solution similar to the "X-ray" function of a supplier. This solution collects supplier-related data, such as cost, delivery cycle, capacity, and inventory, throughout the value chain. And risk. The data sources for this solution will include the proprietary systems of value chain partners, as well as structured third-party data and unstructured web feeds from many different sources, all of which are combined into the company's primary supply chain. Real-time overview of meaning. Many elements of this approach already exist, including network screening solutions designed to improve supplier risk management, and online supplier networks and communities. In the future, we look forward to seeing the convergence of these solutions that will ultimately provide the multi-tier supplier visibility the company dreams of today.

7.eSourcing activities: eRFX, eCatalogs, eAuctions

Electronic procurement tools have been around for more than a decade and have evolved significantly over time. Most vendors now offer kits that include several of these tools, as well as expense analysis and other features. We anticipate that the most important developments in the future will come from automated analysis and user interface improvements, which in our experience is the biggest factor driving adoption. Future solutions will provide more sophisticated analysis, such as bid comparisons or best optimizations, supported by comprehensive, category-specific bidding forms, templates and analysis sets. The power and ease of use of these solutions will greatly facilitate the penetration of digital management and optimized procurement activities.

8. Supplier Collaboration Platform

Compared to business collaboration tools, these applications will facilitate better communication and interaction between external partners, including vendors [tiers 1 to n], research partners and intellectual property providers. They will work like the social networks of the company and its supplier base, enabling better end-to-end cost optimization, faster interaction times, and broader access to external innovation.

Tools to prevent value leakage

Tools to prevent value leakage include ERP and transaction systems to manage purchase-to-pay (PTP) processes and performance management systems. Here, the use of digitization and big data analytics has created some new opportunities.

9. Purchase to payment

PTP workflow. The purchase-to-pay solution was one of the first digital tools to support operational and tactical procurement activities. Since their introduction in the early 2000s, they have evolved significantly in functionality, covering end-to-end processes from purchasing to payment vendors, and extending from requisition management to adjacent areas such as expense management range.

Future PTP tools will use a large amount of order and invoice transaction data to achieve value creation in core business activities. For example, they will create predictive order configurations for repeat buyers, reduce processing time and encourage the use of standard order templates. They will also automatically identify potential suppliers for categories not covered by the contract or catalog, and support the buyer's business strategy by creating more competition.

The buyer's system will be interconnected with the supplier's system to transmit digital purchase orders and invoices without invoice matching: radio frequency identification (RFID), quick response (QR) codes and other receiving technologies that automatically track goods and services will be used. All of this will happen more and more in the cloud, allowing ubiquitous connectivity and significantly reducing processing time and effort, while driving user adoption through procurement and the wider business.

10. Automated compliance management: suppliers, contracts, and buyers

For many companies, especially those with a global manufacturing and service footprint, value leakage remains one of the main sources of unpurchased impact. Advanced compliance management tools will act as a vigilant oversight agency that scans every purchase transaction, including structured (ie ERP systems) and unstructured sources (such as invoices or fees) to identify and quantify value leakage Drive their solutions. Purchases made through the wrong channel will be identified ex-ante (in the PTP tool) or ex-post (during invoice payment).

Advanced compliance management is particularly useful for large, high-value outsourcing contracts, which are typically managed by complex legal frameworks and dozens of individual service agreements and KPIs. The system of the future will automatically read all contract conditions and terms from the contract via machines and match them with continuous invoice flow, supplier activity and performance data. The category purchasing management manager, purchaser, and business owner will then receive alerts about compliance violations and their business impact. Considering the extent of the life-cycle leakage of a typical contract and the high level of manual effort currently applicable to contract governance, the stakes here are huge.

Advanced analytics solutions can also scan and identify non-compliances in transaction-intensive purchases, while manual analysis is not enough-for example, transportation, freight, parcel services, maintenance, repair and operations (MRO), taxis, or hotels consumption. Today, existing point solutions in these areas will increasingly be integrated into comprehensive application packages to address non-compliance issues between suppliers and buyers.

Performance management

11. Supplier Performance Scorecard

The supplier performance management system will be integrated with the above-mentioned supplier "X-ray" function. Such systems will provide real-time insights on supplier performance, gaps, and issues related to expected costs, quality, or lead times. Similarly, they will link to automated service-level monitoring systems and provide integrated claims management capabilities. The availability of this information will enable category managers to act faster and more decisively when problems occur, and provide them with the tools they need to encourage or force suppliers to improve.

12. Purchasing Performance Scorecard

Measuring the overall performance of purchasing organizations and the performance of individual category purchases is the last application we see significant improvements in using digital tools. The above-mentioned category strategic work flow portal [platform and other systems will record all activities of the strategic procurement team, and will simultaneously track all procurement and save strategic innovations. This information will allow the CPO to monitor and manage progress and results, and even adjust to the task level of the category manager as needed. Future workflow solutions will embed these performance management capabilities to manage group, category, and individual performance in real time.