SDLD Precision Optical Technology Corporation is a technology company dedicated to the research and development and manufacture of ultra-precision optical technology, especially the ultra-precision processing of extremely complex optical lenses and high-temperature ceramic materials.

The company has successfully developed China's first large-scale complex micro-nano structure optical mold, the world's first micro-nano textured 3D optical mold, glass Fresnel lens, wafer-level micro-lens array mold and other typical complex optical molds and optical components.

Products

Micro lens array mold

Optical freeform mold

Fresnel lens mold

Head-up display HUD mold for Automotive

High temperature ceramic optical mold

Large-scale complex micro-nano structure optical mold

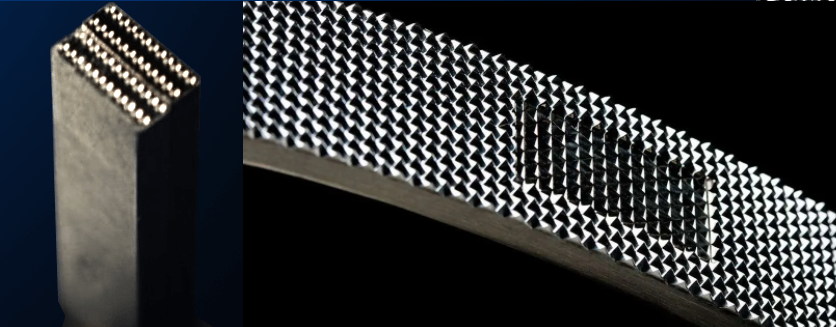

Micro-nano textured 3D optical mold

Wafer-level microlens array mold

micro-nano structure optical mold for Automotive LED headlight

…

Products are used in many fields such as consumer electronics, smart cars, biomedical, optical communication and semiconductor industries.

Wafer-level microlens array mold

Customer Reference

Valeo, Hella, Marelli, Philips…

The company has a 5-axis + ultra-precision machining experimental center, a comprehensive optical testing center, an optical molding clean laboratory, a pure ion diamond coating laboratory, and a supercomputing simulation design center.

Based on the company's core patented technology, SHLD has completed a number of "zero" breakthroughs in localization:

In the consumer electronics industry, the complex microstructure backplanes of Chinese mobile phones have always been imported. The ultra-high-precision molds provided by foreign companies cost hundreds of thousands of dollars. SHLD uses more advanced manufacturing technologies and processes to reduce costs while providing domestically produced products. Substitute and domestically surpassed micro-nano textured mold products.

In the semiconductor industry, SHLD provides core ultra-precision machining parts and components for semiconductor equipment companies, realizing import substitution and product upgrades.

SHLD is one of the few companies in China with full-process solutions from ultra-precision manufacturing equipment, core manufacturing processes to mass production.

The company's core technology "5-axis +" ultra-precision machining: using the world's leading 5-axis + linkage ultra-precision machining, multi-energy field assisted cutting, plasma control polishing technology, to achieve high-precision and high-efficiency manufacturing of complex optical micro-nano structures.

The self-developed multi-wavelength interferometric optical measurement system and embedded in-situ measurement device improve the compensation accuracy and measurement efficiency, and realize the full closed-loop quality control of the whole process.

Innovative research and development of wafer-level optical mold processing technology, large-diameter glass molding equipment system, mass production of high-end visible light and infrared glass optical components, and simultaneous development of quartz optical components in the near-ultraviolet and laser fields.

As a technology development platform, SHLD cooperates with Shanghai Jiaotong University, Harbin Institute of Technology, Zhejiang University, the British National Future Metrology Center, and the Singapore Advanced Manufacturing Research Institute as a basic research carrier, and undertakes industries represented by leading companies in the semiconductor, consumer electronics, automotive and other industries. Industry application research and development needs of application carriers.

With the further promotion of complex optical applications, SHLD will continue to deepen the design, manufacture and R&D in the field of ultra-precision optics.