QDSL Fastening System Technology Company focuses on R&D and manufacturing new rebar splicing technology.

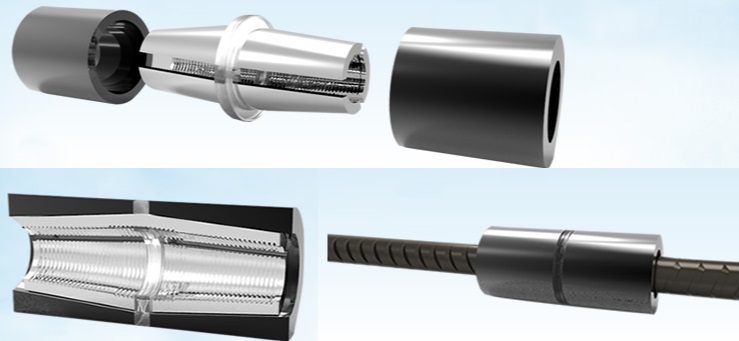

The high-efficient rebar splicing system for the architecture industry. The intellectual property of Taper Sleeve Locking-type Rebar Coupler with the EURO and American patent, ICC-ES, AASHTO, and ASME etc.

The high-efficient rebar splicing system: Taper Sleeve Locking type rebar coupler developed by QDSL has been successfully applied to many large-scale projects in China and internationally:

China's Fuqing Nuclear Power Station, Tian'e Longtan Hydropower Station, Pakistan Karachi Nuclear Power Station…

A few days ago, the China Railway Fifth Bureau Design Institute took the initiative to dock with QDSL to express its willingness to cooperate. After practical verification, the Taper Sleeve Locking type rebar coupler can reduce the use of steel bars and manpower time by 20% to 30%, effectively reducing costs, and plans to incorporate products Engineering design plan.

Taper Sleeve Locking type rebar coupler is an original invention technology in the field of mechanical connection of steel bars in China. It has completely independent intellectual property rights. It has successively obtained 17 invention patents, more than 20 utility model patents and invention patent authorizations in more than 40 countries and regions in Europe and the United States. "Taper Sleeve Locking type rebar coupler has passed the German BAM laboratory, that is, the instantaneous impact load test, the Russian national laboratory’s 2 million fatigue tests in accordance with EU standards, and South Korea’s -50℃ low-temperature tensile test, which can meet the requirements of nuclear power plants. The design requirements of the containment and the use requirements of any regional climate environment.

Do a good job of accurate market positioning, and take effective actions, Taper Sleeve Locking type rebar coupler with unique advantages to let the company occupy a place in the industry. Soon, the company received the first major cooperation project-the main tower project of Guangzhou Humen Bridge.

By using the Taper Sleeve Locking type rebar coupler, the steel reinforcement project for each pouring section of the Humen Bridge has been reduced from the traditional 5 days to 5 hours, and the 3-year construction period has been reduced by a whole year.

When the Fuqing nuclear power plant project was bidding in 2018, their competitor was the French Destar steel joints. In this process, the technical team first carried out impact tests in the French BAM laboratory, passed international certification and was recognized by customers, especially French technical parties, and then successfully won the bid with a price advantage of 1/2 lower than DSD.

Subsequently, in specific project applications, the advantages of the Taper Sleeve Locking type rebar coupler were once again highlighted. Because the traditional steel joints require welding and other processes, 4 to 5 meters of holes must be reserved for the operators to enter and exit, and they will be sealed after the completion of the project. However, the taper sleeve locking rebar joint is easy to operate and does not need to reserve an opening. In this way, it not only reduces the construction difficulty and labor intensity of the operators, but also saves the plugging cost for customers.

The pile foundation construction of Luoyang Metro Line 1 is one of the projects actively seeking cooperation, because the subway construction site is located in the urban area, and the smoke and radiation pollution generated by traditional welding connections have seriously affected the lives of local residents. The taper sleeve locking reinforcement joint not only does not require welding, but also reduces the pile setting time from 10 hours to 35 minutes, which improves work efficiency and reduces the risk of wall collapse. The on-site operators gave the company’s technicians a thumbs up many times: "Your joints are not only easy to operate and easy to use, but also save our welding process!"

Today, the company has developed 5th generation steel bar connection products, 6th generation supporting connection equipment and several construction auxiliary accessories and other products. The construction quality, construction methods, safety and environmental protection are all at the international leading level. Not long ago, the Design Institute of China Railway Fifth Bureau docked with the company, hoping to use taper sleeves to lock the steel joints in the upcoming Sichuan-Tibet railway project.

"Taper Sleeve Locking type rebar coupler fully meets the harsh environment's strict requirements for products. The convenient and efficient operation method can reduce the labor intensity and time of the operators, and reduce the harm to the human body caused by the harsh environment." The technical person in charge of the design institute said This is the evaluation.