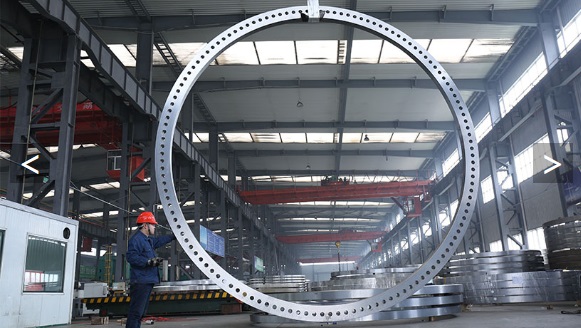

On November 25, Chinese leading manufacturer of Heavy Steel Forged Seamless Rolling Ring, the super large forging ring developed by SDYL with a weight of 165 tons and a diameter of 7.6 meters successfully rolled off the production line. This product not only created the largest size record of similar products, it was also the first 3,500 kJ marine hydraulic piling hammer with independent intellectual property rights in China.

Function of super large ring forging

The hydraulic piling hammer is mainly used in the foundation construction of offshore wind power single-tube piles. It is driven by a hydraulic system to generate a huge impact force, thereby driving a steel pipe pile weighing one or two thousand tons into the seabed as a whole. For the 3,500 kJ pile hammer, its single blow energy is equivalent to the kinetic energy produced by a 100-ton object from a free fall from a height of 3.5 meters to the ground. All of this energy must be borne by the ring driver and effectively transmitted. Pile pipes, so ringing is one of the key components of the whole equipment.

This technology "means that China is fully capable of manufacturing piling equipment with stronger strike capabilities and larger construction diameters in the future. This is of great significance to our future development and installation of offshore wind turbines over 10 MW." SDYL Technology Research and Development Deputy General Manager Yin Wei introduced to Hay Think.

At present, only a few companies in Germany and the Netherlands are able to manufacture super-large pile hammers of more than 3,000 kJ in the world. The maximum of similar equipment developed by China before is 2500 kJ.

This time, the 7.6-meter-diameter replacement forged ring has broken the previous limitation that similar products can hardly exceed 7.5 meters in diameter. It is a rolling ring with a special section rolled on a 16-meter ring rolling mill. The rolling success of this rolling ring has reached the international advanced level. It is of great significance for China to develop larger diameter piling equipment in the future to serve the development of my country's large-megawatt offshore wind power.

About SDYL

SDYL Heavy Equipment Technology Group is a manufacturing concern that specializes mainly in a diversified range of products within the forgings industry. Our main products include discs, rings, hollows and special-shaped forgings; grinding balls, rods and liners, mainly used in fields such as wind power, nuclear power, UHV, petrochemical, offshore engineering, machinery manufacturing, mining and other fields.

Advanced Seamless Ring Rolling Forgings technology

SDYL has an important market position in the fields of clean energy, fossil energy, heavy equipment and mining, including:

In the field of wind power, we are the main manufacturer of tower flanges in China, and provided tower flanges for DTC 10MW and GE 12MW;

In the field of nuclear power, we maintain a manufacturing record of diameter 15.8 meters in forging rings worldwide;

In the field of pipe flanges, we have more than 20 years of export experience, and obtained the certification of the eight countries classification society;

In the field of mine grinding, our export volume of forged grinding steel balls ranks among the top five in the industry;

We have participated in drafting and formulation of 8 industry and association standards regarding wind turbine ring type forging, forging rolling grinding ball, UHV tubular tower flange and forging rolling large cylindrical forging etc.

SDYL's history can be traced back to 1980. It now has 1 sales company, 5 business divisions, 7 management centers and 1 overseas factory, covering an area of 350,000 m2 and having over 1,400 employees. For nearly half a century, SDYL has always been steadfastly devoted to the forging industry. From offshore wind turbines on the Atlantic coast to the oil fields deep in the deserts of the Middle East, to mines in the lofty mountains of Peru, our products have made their mark.

Products

Large-Size Seamless Rolled Ring Forgings

SDYL's total investment in our Large Forging Project exceeds 600 million yuan and covers an area of 80,000 square meters. The project relies on the Academician Li Yiyi Workstation, established with the Institute of Metal Research of the Chinese Academy of Sciences, to research and manufacture large forgings of high-alloy steels and non-ferrous metals.

This project applies the latest CNC and smart equipment of forging, heat treatment, and machining equipment including a hydraulic press of 13,500 tons, hearth 8m wide trolley heating furnace, a split heat treatment furnace with an internal diameter of 7.5 meters, a bore type heat treatment furnace with a diameter of 17.5 meters, a quenching sink of 19 meters in diameter and 5 meters in deep, and other large heat treatment equipment, as well as 16 meter turning diameter CNC machinery and other large CNC machining equipment. The RAW 2500/ 1250-16000/3000 ring rolling machine imported from SMS Meer, Germany for the project is the world's largest radial-axial rolling machine.

Wind turbine forgings

Wind turbine ring forging is an important part of the wind turbine system. SDYL provides products such as tower connecting flanges, overall forged door frames, ring forgings for bearing gears and leaf blade flanges. SDYL has rich manufacturing experience in this field. Our tower flanges are used in more than 1/3rd of wind turbines in the Chinese market, and the proportion is even higher in offshore wind power, where it accounts for more than 50%. We are a certified supplier of Vestas, Siemens, Gamesa and GE, and have sold our products globally. With respect to large megawatt wind turbines, the vast majority of 5MW wind power units in China use our flanges at the prototype phase. In 2015, we provided several tower flange sets for Vestas' 8MW turbine, and in 2017 we provided 60 basic spacer flange sets for Siemens' 7MW turbine used in the British EA One project. We have participated in compiling the "Ring Type Forgings of Wind Turbine Generator System" standards developed by National Ene rgy Administration, and the "Precision Forming Technology and Equipment for Wind Turbine Ring Forgings" is listed in China`s Torch Plan.

Pipe/Pylon Flange

The pipe flange is one of the earliest products of SDYL. The company possess 40 years of manufacturing experience and 20 years of export experience for pipe flanges. The product has passed classification society certification in eight countries, CE PED certification, Canada CRN certification, API , and Petrobras certification. The different types of forging materials (forged parts) produced by SDYL are highly valued by local and global customers.

Our cable tower and pylon flanges are sold to many renowned enterprises such as the China State Grid and French BOMA, which have widely applied our products in many domestic UHV electricity transmission lines.

Disc Forgings

Disc forgings, also called forged discs or plate forgings, are a component made by forging (thickening or lengthening) the heated materials on the forging equipment. Through thickening, the height of the materials is reduced and the diameter is increased. The internal fiber line is transferred from being horizontal with the axis to being radial with it. The metal grains are also refined and improved in this process. Therefore, compared to discs cut from plates or rods, forged discs have greater hardness, toughness, impact strength and fatigue resistance .

Ring Forgings

SDYL occupies a very important position and has rich manufacturing experience and success in the ring forgings in China and global market. SDYL is the chair unit of the ring forging committee for the Confederation of Chinese Metal Forming Industry. SDYL has 9 vertical & horizontal ring rolling production lines with various machining modes. We can provide all kinds of small and medium ring forgings such as bearing collars and aluminum magnesium alloy ring forgings used in GIS gas insulated switchgear system, and large-scale forgings and extra-large ring forgings for wind turbines , large-scale semi-autogenous mill, harbor machinery and TBM (tunnel boring machine). We also introduced the world's first super-grade rolling mill from Germany's SMS Meer, which can manufacture rings with a diameter up to 16 m and height up to 3 m.

Forged Hollows

Forged hollows are widely used in high temperature/pressure and other harsh conditions, such as hydrogenation reactors, nuclear reactor pressure vessels, evaporators, submarine oil and gas pipelines, etc., thanks to their durability, anti-corrosion features, high strength and long service life. SDYL uses high-precision CNC rolling mills to manufacture forged hollows using the ring forging process, which, aside from shortening the lead time, also assures compact internal structure, fine grains and complete circumferential flow of workpieces, thus further improving the strength , wear resistance and fatigue resistance. Also, all kinds of workpieces with variable diameter can be manufactured using molds of different shapes.

Certificates:

9001 Quality System Certification Certificate

ISO14001 Environmental Management System Certification

ISO18001 Occupational Health Management Certification

National Laboratory Accreditation Certificate

CPR EU Building Directive Certification

EN1090 EU Material Certification Certificate

Gamesa Certificate

Japan Ministry of Economy, Trade and Industry flange performance certification certificate

PED

TUV

Vestas Certificate

ABS American Bureau of Shipping Certification

BV Bureau Veritas certification

CCS China Classification Society certification

CLASSNK Japan Classification Society certification

DNV-GL Det Norske Veritas Certification

KR Korea Classification Society certification

LR British Register of Shipping

RINA Italia Certification