Hydrogen fuel cell vehicles (FCV) have become the development trend of future automobiles due to their zero-emission characteristics. The hydrogen storage bottle used to store high-pressure hydrogen is one of the essential key components of fuel cell vehicles. Hay Think summarized the key technical difficulties faced by the research and development of type IV hydrogen storage cylinders, including the selection and molding process of inner tank raw materials, sealing structure design, resin modification development, lightweight design and fiber winding, and on this basis, respectively The research status at home and abroad is introduced.

Hydrogen storage is a bridge connecting hydrogen production and hydrogen use, and plays an irreplaceable role in the development of hydrogen energy. So far, almost all hydrogen storage equipment and hydrogen transmission equipment have been subjected to hydrogen pressure, and are pressure-bearing equipment in special equipment, among which gas cylinders are a more common type. With the rapid development and industrialization of hydrogen fuel cells and electric vehicles, type IV hydrogen storage cylinders are becoming a research hotspot in the world due to their light weight and fatigue resistance. Type IV hydrogen storage cylinders in Japan, South Korea, the United States, China, Norway and other countries The hydrogen storage cylinders have been mass-produced, and other countries also have related plans to increase the research efforts on Type IV cylinders.

1. The purpose of the OSIRHYS Ⅳ project funded by the French ANR research institute is to break through the technical bottleneck of type IV cylinders, and solve the technical difficulties of 70MPa type IV cylinders from the aspects of simulation, design, and trial production;

2. The UK TSB funded the country’s HOST project, which plans to invest 1 million pounds to research composite gas cylinders with thermoplastic inner tanks;

3. The U.S. Department of Energy (DOE) began planning hydrogen storage research as early as 2002. After more than 10 years of development, DOE's research reports have covered hydrogen production, storage, transportation, and use.

On November 28, 2019, Plastic Omniun Type IV Hydrogen Storage Cylinders passed all R134 certification tests.

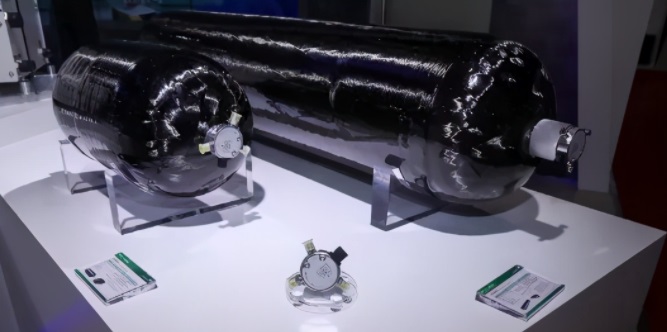

Type 4 high-pressure Hydrogen storage cylinders developed by Chinese manufacturer SYSL

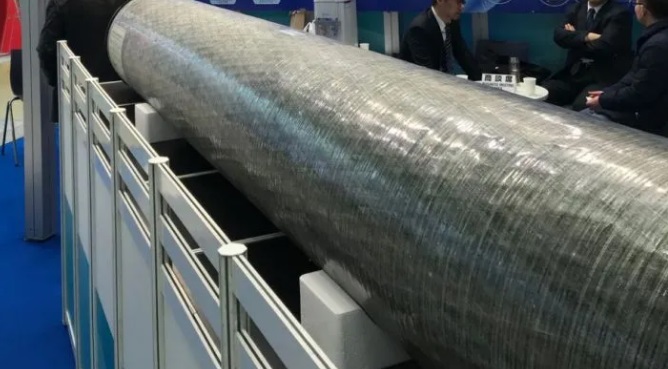

Fully wound Type 3 high-pressure cylinders with carbon fiber aluminum inner tank developed by Chinese manufacturer ZCKJ

Faurecia Type 4 high pressure Hydrogen storage cylinders

Type 4 high-pressure hydrogen storage cylinders developed by Japanese manufacturer JFE

Ultra-light composite hydrogen cylinders developed by ILJIN Composite in South Korea

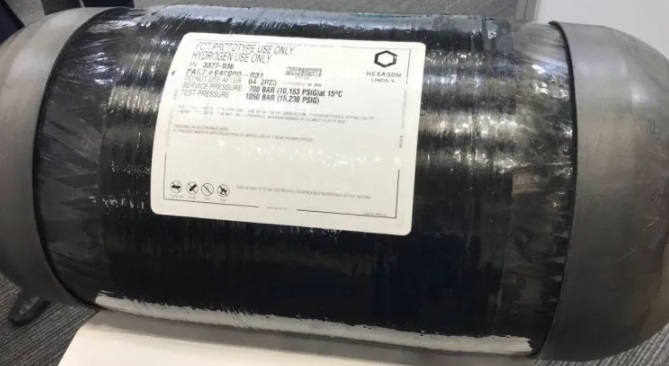

Type 4 high-pressure Hydrogen storage cylinders developed by Hexagon Group

Type 4 high-pressure Hydrogen storage cylinders developed by German manufacturer NPROXX