HNXD is committed to the R&D and manufacturing of high-performance hard alloy precision components.

We provide solutions and personalized customization services for high-end wear-resistant components and complex system integration components in industries such as global oil and gas drilling and production, chemical smelting, and engineering machinery. The vast majority of our products are sold to developed countries in Europe and America such as the United States and Germany. We have been responsible for the manufacturing of oil and gas drilling and production tools for the Fortune 500 oil and gas service companies for 16 consecutive years.

HNXD is a Hidden champions in the field of cemented carbide deep processing in China.

The company currently has 109 authorized patents (9 international patents), including 37 invention patents. The company has passed ISO9001-2015 quality system certification, AS9100D aerospace quality management system certification, API-Q1 petroleum industry quality management standards, and GB29490-2013 enterprise intellectual property management system certification.

The HNXD independent research and development project – "Composite Forming Technology for High end Hard Alloy Wear-resistant Parts" won the third prize of the "Provincial Technology Invention Award" in 2018, and the patent for "A Composite Hard Surface Material and Its Preparation Method" won the "Outstanding Award of the 22nd China Patent Award" and the first prize of the "Hunan Province Patent Award" in 2019, The project "Preparation and Application of Special Hard Surface Materials for Petroleum Drilling" won the third prize of the "Provincial Science and Technology Progress Award" in 2020, and the patent "A Hard Alloy Composite Forming Method" won the third prize of the "Provincial Patent Award" in 2020.

With the R&D and application of advanced hard wear-resistant structural materials as the technical core, the company is proficient in surface strengthening and remanufacturing of professional metal materials, and has accumulated precipitation in the integrated precision manufacturing and processing capacity of high-end wear-resistant core components and key systems. It has a professional R&D team covering materials, machinery, Fluid mechanics and other professional fields, and has long-term and in-depth R&D cooperation with many 211 and 985 well-known universities and colleges.

HNXD has become a high-end wear-resistant component deep processing enterprise in the field of oil and gas drilling and production in China, with its strong technical and service capabilities, forming its own characteristics and core business advantages.

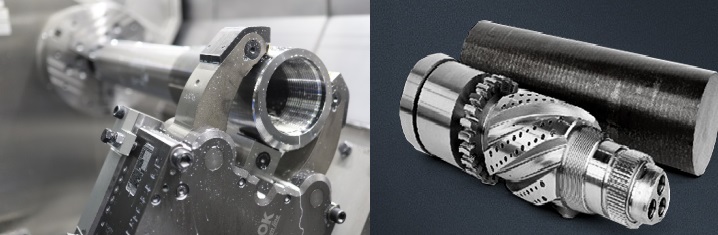

Precision hard alloy products

Cemented carbide is a kind of alloy material which is made of hard compound of Refractory metals and bonding metal by powder metallurgy process.

It has high hardness, wear resistance, good strength and toughness.

Hard alloy can be used to make rock drilling tools, mining tools, drilling tools, measuring tools, wear-resistant parts, metal molds, cylinder liners, precision bearings, nozzles, and so on. Xidi hard alloy products mainly include nozzles, valve seats, valve sleeves, logging parts, valve trims, sealing rings, molds, teeth, rollers, rollers, etc.

Production capacity of overall tungsten carbide parts:

Maximum size: 450 * 450mm

Minimum size: 0.5 * 0.3 * 1mm

Hard alloy teeth

Hard alloy PDC base

Hard alloy threaded nozzle

Hard alloy nozzle

Hard alloy ordinary nozzle

Carbide shaped nozzle

Hard alloy long neck nozzle

MWD logging parts

Hard alloy logging parts

Hard alloy valve seat

Hard alloy liner

Hard alloy valve seat

Hard alloy valve cage

Hard alloy wear-resistant straight pipe

Hard alloy sealing ring

Hard alloy valve sleeve

Precision machining

Material range (commonly used)

·Carbon and carbon steel: 45 #, 20 #, 1020

·Alloy steel: 4140/4145, 4330V, 4340

·Alloy Tool steel: D2, S7

·Mold steel: H13

·Austenitic stainless steel: 316L, 304, UNS31803

·Martensitic stainless steel: 17-4PH, 410, 420

·Duplex stainless steel: 2205

·High temperature alloys: Inconel718, 625, 725, 925, etc

·Non magnetic steel: P550

·Titanium alloy: TC4, TC11, TA6

·Copper, aluminum

The company has a huge procurement system and supplier network, which can purchase different types of steel and imported steel in the market according to customer customization requirements

Product features (deep holes, eccentricity)

·The company has obtained the API Q1-3702 qualification certificate, obtained thread processing qualifications from multiple customers, and has rich experience in thread processing and software and hardware facilities

·The company specializes in the processing of high-precision machining parts for shafts within 3 meters (please consult us if you exceed this size),

·The aspect ratio of deep blind hole processing reaches 40 times,

·Suitable for processing various high-precision, special materials, eccentric internal shapes, elbows, and complex geometric parts.